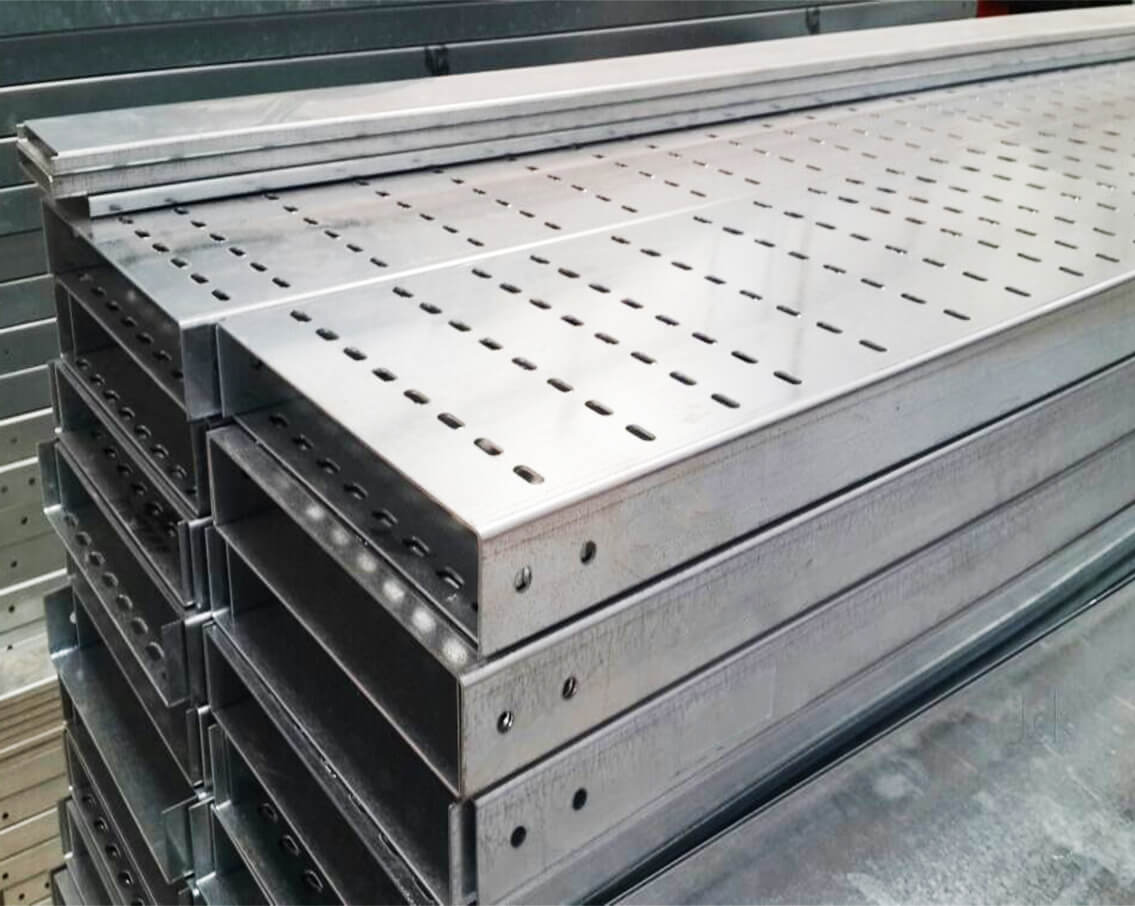

Hot-dip galvanized cable tray is a type of cable tray but is coated with a layer of zinc on the surface to protect the cable tray from environmental agents such as rust, peeling paint surface. Installation of hot-dip galvanized cable trays is usually suitable for outdoor projects with large steel structures such as oil and gas rigs, hydroelectric dam gates, factories, factories, etc. and places with highly corrosive environments. Please refer to the following article with P69 Joint Stock Company.

What is hot dipped galvanized cable tray?

Applying the most advanced zinc coating technology on the market, hot-dip galvanized cable tray products are known for their anti-rust, anti-oxidation and very high durability when used. This line of cable trays is often used in construction works in highly corrosive environments such as hydroelectric dam gate systems, ship hulls or oil and gas rigs…

Application of hot-dip galvanized cable tray

Hot-dip galvanized cable tray is a high-strength product with good resistance to be used in the installation of outdoor cable tray systems where there is high corrosion, chemical plants, etc.

Popular works using galvanized cable tray:

- Oil and gas plants, oil refineries.

- Chemical factory.

- Outdoor works at stone workshops, mineral workshops, etc.

- Thermal and hydroelectric power plants.

- Factories near the sea, etc.

Advantages of using hot-dip galvanized cable trays

Some advantages of hot-dip galvanized cable trays include:

- Cable tray protection is very good, especially in environmental conditions with corrosive agents, oxidizing agents, adapting to outdoor environments.

- High aesthetic factor

- Competitive hot-dip galvanized cable tray quote

- The product’s service life is long, so it saves a lot of repair, maintenance or replacement costs

- Simple design, easy installation and does not take much time to complete

- High-tech hot-dip galvanized cable tray

- There are many sizes to meet many different projects

Features of hot-dip galvanized cable tray installation

Users often give great preference to product hot-dip galvanized cable tray because it has many outstanding features. This is also a factor that helps this cable tray line to compete effectively in the market.

- Firstly, the cable tray is plated with zinc, so it will help the product adapt effectively in acidic environments. Oxidation or rust will be minimized. Therefore, the cable tray will have longer-lasting durability.

- Second, the high-temperature hot-dip technology helps the product to have a beautiful flower pattern. This is not only the aesthetics of the cable ladder alone but also contributes significantly to the overall aesthetic of the building in which it is selected to install.

- Third, because the cable tray is durable, users will certainly save money on maintenance, repair or replacement. This is the factor that makes more and more users trust this cable tray line.

- Fourth, compared to powder-coated cable trays, this cable tray line has a much more favorable price. Meanwhile, the efficiency of use is not inferior. This option will be a very effective economic solution that users cannot refuse.

- Fifth, the product design is simple, the size is compact, so it also makes installation or transportation much easier.

The latest hot-dip galvanized cable tray price list 2022

There are many product lines on the market that provide electrical cable trays for customers to choose from. These can be mentioned as: powder coated cable tray; hot-dip galvanized cable tray or galvanized cable tray… Each type will be manufactured with different characteristics and uses. Of course, the price list listed on the market is not the same.

Besides, each supplier also has a different product quality and price policy. Therefore, before making a decision to choose which product to trust, customers need to carefully consider their needs, financial conditions and suppliers. Only then, the new selection really brings the desired effect.

P69 company updated the price list of hot-dip galvanized cable tray 2022 for the following reference:

| No. | WIDTH | HEIGHT | UNIT |

UNIT PRICE (VND)(due to tole’s thickness)

1.0mm/1.2mm/ 1.5mm/ 2.0mm |

|

| HOT DIP GALVANIZED CABLE TRAY | |||||

| STANDARD LENGHTH 2500, 3000MM | |||||

| 1 | Hot-dip galvanized cable tray 50X50 | 50 | 50 | M | Contact |

| 2 | Hot-dip galvanized cable tray 60X40 | 60 | 40 | M | Contact |

| 3 | Hot-dip galvanized cable tray 75X50 | 75 | 50 | M | Contact |

| 4 | Hot-dip galvanized cable tray 100X50 | 100 | 50 | M | Contact |

| 5 | Hot-dip galvanized cable tray 100X75 | 100 | 75 | M | Contact |

| 7 | Hot-dip galvanized cable tray 150X50 | 150 | 50 | M | Contact |

| 8 | Hot-dip galvanized cable tray 150X75 | 150 | 75 | M | Contact |

| 10 | Hot-dip galvanized cable tray 200X50 | 200 | 50 | M | Contact |

| 11 | Hot-dip galvanized cable tray 200X75 | 200 | 75 | M | Contact |

| 15 | Hot-dip galvanized cable tray 250X100 | 250 | 100 | M | Contact |

| 16 | Hot-dip galvanized cable tray 300X50 | 300 | 50 | M | Contact |

| 17 | Hot-dip galvanized cable tray 300X75 | 300 | 75 | M | Contact |

| 21 | Hot-dip galvanized cable tray 350X100 | 350 | 100 | M | Contact |

| 22 | Hot-dip galvanized cable tray 400X50 | 400 | 50 | M | Contact |

| 23 | Hot-dip galvanized cable tray 400X100 | 400 | 100 | M | Contact |

| 25 | Hot-dip galvanized cable tray 500X50 | 500 | 50 | M | Contact |

| 27 | Hot-dip galvanized cable tray 500X150 | 500 | 150 | M | Contact |

| 28 | Hot-dip galvanized cable tray 600X100 | 600 | 100 | M | Contact |

| 29 | Hot-dip galvanized cable tray 600X150 | 600 | 150 | M | Contact |

| 31 | Hot-dip galvanized cable tray 1000X150 | 1 | 150 | M | Contact |

| 32 | Hot-dip galvanized cable tray 1000X200 | 1 | 200 | M | Contact |

Contact P69 Joint Stock Company via hotline: 02422121212 – 0965937799 for a specific product quote!

Hot-dip galvanized cable tray installation process

Different projects will have different installation requirements for cable tray systems to ensure that the technical designs are achieved. However, there is still a common installation process for hot-dip galvanized cable trays, which must go through the following general stages:

1. Step 1: Check the details and components of the cable tray ladder system

Make sure you have enough materials for the system.

Each component of the cable ladder will not be the same, need to carefully check the included accessories.

In some cases, cable ladder components require a certain amount of:

- Ladder

- Cable frame

- Adapter frame

- Platform frame

- Ground strap

- Types of screws

- Gaskets and bolts

Therefore, construction investors need to pay attention to choose reputable production units, good product quality and suitable prices.

2. Step 2: Cut the cable tray ladder, bracket legs to the right size

In case the ladder and the frame are incompatible sizes, the ladder needs to be cut so that the two sizes fit together. Each ladder cuts approximately 2 inches off the required length. While cutting, care must be taken to ensure no injury.

3. Step 3: Fix the cable tray ladder to the wall

Attach the stand to the wall, or other intended support points of the cable ladder. Normally, brackets that will be attached to the wall will be connected. If not, a hole in the wall of the right size needs to be drilled for mounting. Then, place the adapter bracket into the holes on the top of each cable ladder.

Make sure that the hooks of the adapter frame are facing down and the cable ladder is on top. When installing the bracket on the wall and the adapter frame inside the ladder, the ladder can be pinned in the center of the wall.

4. Step 4: Attach the support for the cable tray ladder to make sure it is secure

With today’s ladder frames simply pin to the ladder without the need to install anything extra. The contractor needs to install the safety frame before proceeding to the next step. Because if the frame is of poor quality, it will lead to a high degree of danger and risk. In some cases a ladder frame requires additional installation, it is usually the attachment of ladder frames to the cable ladder with nuts, bolts and washers.

5. Step 5: Ground the cable tray ladder

Grounding the cable tray ladder is an extremely important step in preventing electric shock. Although the content of grounding is not mentioned in the technical requirements of the cable tray ladder, this is an action that needs to be taken to prevent future risks. In addition, each sheath or cable ladder rack needs to be grounded.

First, connect the foundation frame to the cable tray at a point near the wall. Then you attach the ground strap to the platform frame with nuts. Finally, you attach the ground strap to one of the grounding points in the wall.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Headquarter: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02422121212 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube: https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA