In the construction process, besides the quality, the method of construction and installation of HDPE water pipes in accordance with the technical process is essential and important. That will help the pipeline be sure, not damaged and not have any problems during operation and operation. This also helps users reduce the burden of repair costs. Let ‘s learn about the construction and installation process of the following standard HDPE water pipes with P69 Company

What is HDPE pipe?

HDPE plastic pipe is the abbreviation of density polyethylene, this is a type of pipe using thermoplastic polyethylene material from the oil refining process with relatively high strength. The density of HDPE pipes can be in the range of 0.93-0.97 g/cm3 or 970 kg/m3.

Although HDPE pipe has a relatively low density, because of its little branching, it has a strong intermolecular force, so it has a high tensile strength.

For nearly 50 years, HDPE pipes have been used to transport liquids, with strong pressure resistance and good resistance to oxidation or external influences.

In addition, HDPE welds are used with heat sealing tools, so the possibility of leakage is very unlikely, improvements in HDPE pipes are often used for city, family and domestic water supply pipes. drainage pipe company, large enterprise

Size and diameter of HDPE pipe

HDPE pipe sizes are usually classified according to the following size standards:

+ Phi 20, 25, Ø 32, Ø 40, 50, Ø 63, Ø 75, Ø 90, Ø 110, 125, Ø 140, Ø 160, Ø 180, Ø 200, Ø 225, Ø 250, Ø 280, 315, 355, Ø 400, 450, 500, 560, Ø 630, 710, 800

+ Material standards: PE100, PE80

+ Pressure: 6PN, 8PN, 10PN, 12PN, 5PN, 16PN, 20PN

Classification of HDPE pipes

Non-pressurized pipeline

These pipes use gravity to work by transporting the flow from higher places to points of consumption

The feature of this pipe system is that it does not require a motor or any other power. Easy to manage and simple to operate. Widely used in places with favorable terrain, with high slope

Pipes with pressure

With this pipe system, we need to use a booster pump to increase the water pressure in the supply pipe to the water-using equipment, this system has the following characteristics:

Easily manage water pressure in pipes

The ability to supply water is more efficient

The system is not affected by terrain

The installation process needs to be done carefully to avoid strong pressure that will break the pipeline and cause water leakage

Advantages and disadvantages of HDPE pipes

HDPE pipes are widely used as drainage pipes, water supply pipes. So what are the pros and cons of the product? Plastic pipes are very durable, not corroded by strong chemicals, not oxidized. Products with high durability should save installation and repair costs.

In addition, the material has a variety of pipe sizes, providing many choices for customers. HDPE pipes are very malleable, suitable for complex terrains zigzagging in the ground.

Besides, the drawback of this product is that it is very difficult to fix the joints of plastic pipes if damage occurs.

Instructions for construction and installation of standard HDPE water pipes

Here , company P69 would like to introduce to you some steps to install HDPE water pipes. These steps are carefully selected and tested for the output information, so you need to take care to keep it.

Step 1: Design drawings of construction methods for HDPE water supply pipes

In order to properly comply with the technical requirements during the construction of HDPE water supply pipes, you need to have detailed drawings and complete calculations to avoid damage, going wrong in the process, and costing repair.

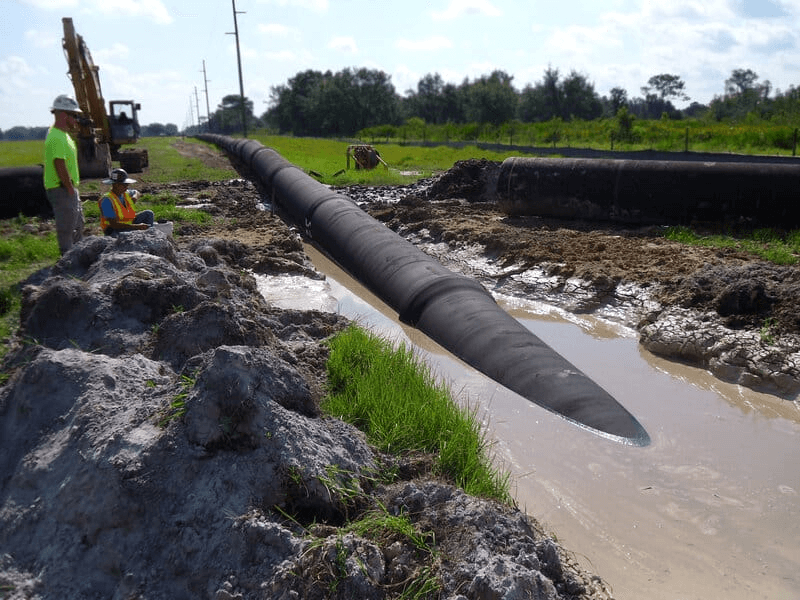

Step 2: Dig trenches

This is the first thing to do before the construction of HDPE pipes. The width of the groove is determined by the number of pipes intended to be placed. You must make the pipe at the top position at least 0.6m higher than the ground surface (normally) or 1.2m (if subjected to high pressure).

The bottom pipe should not be placed on hard rock or pebbles, but should be placed on a leveled and hand compacted sand bed. Construction personnel need to know these skills to ensure good and durable pipes.

Step 3: Place the tube:

Cut the pipe with a special tool so that it is perpendicular to the center line of the pipe. Bevel the ends of the pipes for easier installation. Then disassemble the cap and push the cap with the tightening ring with the stop ring into the tube.

Continue to push straight through the center of the tube end into the fitting, passing through the gasket until it touches the ledge on the body of the fitting. Tighten the cover by hand, but without touching the outer edge of the accessory body. Then fasten the cover to the body of the accessory.

Step 4: Fix the pipe and fill the groove

If there is more than 1 HDPE pipe in the trench, the last action is to fix the pipe. The distance between pipes must meet the following criteria:

+ For pipes with inner diameter from 25mm – 70mm, the distance left – right and top – bottom is 50mm.

+ For pipes with an inner diameter of 80mm – 160mm, the distance left – right and top – bottom is 70mm.

+ For pipes with inner diameter from 175mm – 250mm, the distance left – right and top – bottom is 100mm.

Step 5: Carry out the steps of welding PPR . plastic pipes

To perform welding of plastic pipes, it is necessary to require highly skilled technical staff to perform it carefully.

First, you need to prepare a pipe welding machine, plug it in to 220V at a temperature of 260 degrees Celsius. Next, you need to prepare the necessary plastic pipes and fittings for the connection. should clean the pipe end surface before placing the pipe in the welding machine to ensure the connection is strong.

The last step in the construction method of HDPE water supply pipe is to conduct fusion welding. This stage requires to ensure that the solder is perpendicular to the welding tip.

Notes when constructing and installing HDPE water pipes

During the construction of the water supply pipe, you should pay attention to the following points:

- In case the HDPE pipe is clogged, it is necessary to use a water pump to remove all sand, mud and dirt to unclog the pipe.

- In case the plastic pipe has lost its bait wire, it is necessary to use specialized bait lines. Or use PVC pipes together with requirements to ensure the required length.

- Note that the construction stages need to ensure the correct technical requirements, be careful to avoid mistakes that cause great damage.

- In addition, it is necessary to ensure labor safety, full protective equipment to avoid unfortunate accidents.

The construction of the water supply pipe needs to comply with the required process to ensure labor safety and ensure the quality of the work meets the standards.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E . M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA