UPVC plastic water pipes are more and more widely used in life, gradually replacing cast iron, steel and cement pipes because it has many outstanding advantages. Currently, the installation of uPVC water pipes in civil construction works is indispensable. However, through the process of use, it is inevitable that the water pipe will be subject to collision, contact, wear and tear, causing bursting and leaking of water pipes. Today, P69 Company will offer ways to install uPVC water pipes, as well as the advantages and outstanding features of uPVC water pipes for your reference.

What is uPVC water pipe?

UPVC pipe, also known as UPVC plastic pipe, is an abbreviation of the phrase “unplasticized Polyvinyl chloride”. This is a form of PVC pipe and is currently being widely used in the market because of its superior features compared to previous generation PVC pipes.

uPVC pipe is manufactured in the form of bars, has a box structure, is divided into many spaces with the function of sound and heat insulation, creating durability for the product and bringing high economic value.

uPVC pipes include two types:

– Rigid uPVC pipe, also known as uPVC pipe

– Soft uPVC pipe.

Outstanding advantages of uPVC water pipes

Thanks to the materials that make up the uPVC pipe product line. So the product line has many outstanding features that other plastic pipes do not have. May be mentioned as:

– uPVC pipes are lightweight, so they are easy to transport in constructions.

Besides, this is a type of plastic pipe with a ball inside and outside, a small coefficient of friction.

– uPVC pipes are capable of withstanding high pressure.

– Installation is light, accurate, durable, waterproof.

– uPVC pipes have high mechanical strength and impact resistance. Using the correct technical requirements, the durability of uPVC pipes is very large

– Low cost, low installation cost compared to other types of pipes.

– High chemical resistance (at temperatures 0oC to 45oC, resistant to acids, alkalis, salts.)

Outstanding applications of uPVC water pipe installation in life

With the above outstanding features, uPVC pipes are widely applied in life. May be mentioned as:

- Installation for sewage system, rainwater drainage.

- Installation of clean water supply • Installation of water supply pipes for irrigation in agriculture.

- Installation for pipe systems to protect power lines, signals, and optical cables.

- Wide range of industrial applications

Methods of installing uPVC water pipes

Through the process of use, it is inevitable that the water pipe will be collided, exposed, worn out, causing bursting and leaking water pipes. Today, P69 Company will offer 4 ways to install uPVC water pipes to easily overcome the above problems.

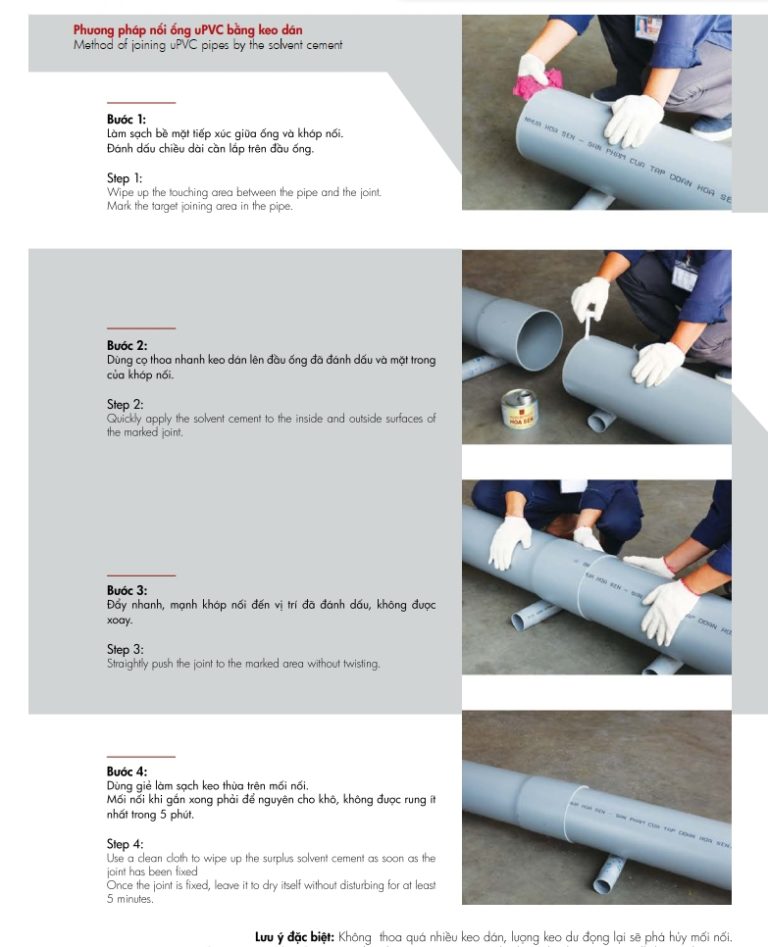

1. Install uPVC water pipes by gluing method.

Applicable sizes of uPVC pipes with diameters from 21mm – 250mm.

Commonly used to connect pipes to pipe sockets or to connect pipes to fittings.

Attention:

Pipe connectors must be cut perpendicular to the shaft and beveled for larger diameter pipes.

The surface to be joined must be clean, dry and free of grease

Apply an even layer of glue to the part that needs to be connected to the end of the pipe and the socket

Clean the surrounding glue immediately after attaching the coupling

Let the joint dry for at least 5 minutes

For pipes with diameter > 200mm, special joining technique is required

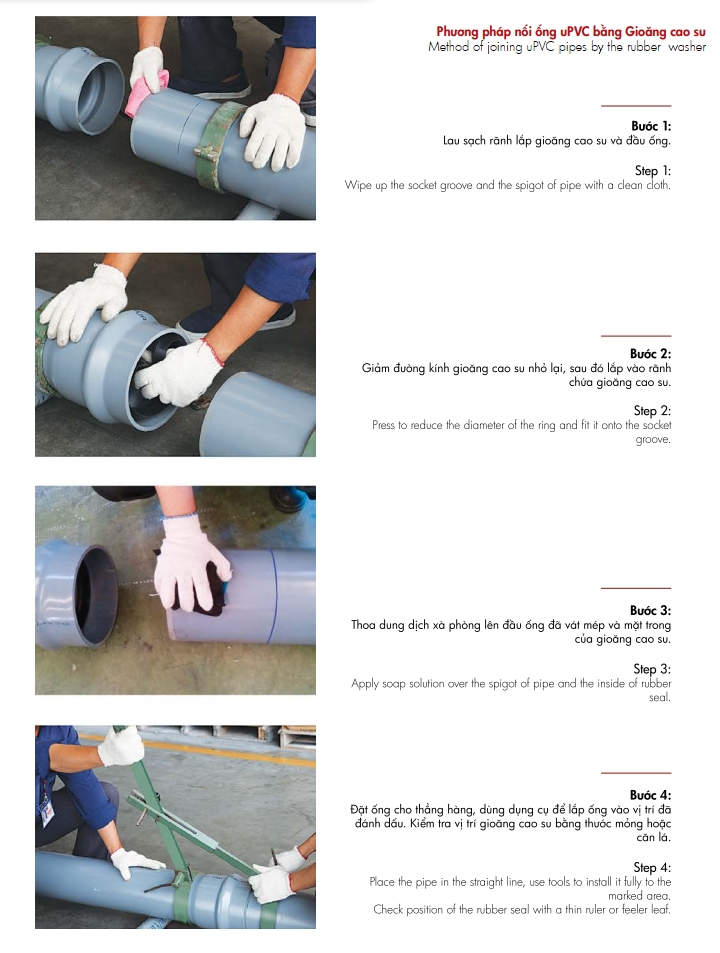

2. Installation method using a socket with rubber gasket.

Applicable to uPVC pipe sizes greater than or equal to 63mm, sockets with rubber gaskets.

Commonly used to connect to the socket of a hose or to connect the hose to the socket of a hose fitting with a rubber gasket.

The elastic rubber gasket will self-compress and create a sealed joint when the tube end is inserted into the socket with the rubber gasket.

Attention:

The connector must be cut perpendicular to the shaft and the pipe end bevel

Before installing the water pipe, mark the mounting length on the smooth end of the pipe

Hose connectors should be lubricated prior to insertion, if necessary.

As soon as the end of the pipe is lubricated, insert it immediately into the connector and press the end of the pipe until the mark is marked.

3. Plastic flange connection method.

Used to join uPVC pipes together and to join uPVC pipes with metal flanges, valves and with flanged fittings.

4. Thread splicing method

– Applies to threaded joints for connecting pipes to metal pipes or fittings including:

+ Fittings for the transition of u.PVC pipes

+ Fittings for the transition of u.PVC and metal pipes

Attention:

– PVC lace has not good tolerance, so it is easy to leak

Contact us today for a free consultation and answer at:

Contact information P69 – M&E . M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA