You are in need of using a Chiller system, but you do not have much information about the product and do not know well about this product. Don’t worry, all your problems will be solved. In this article, P69 Company will share with customers and help customers answer the question what is a chiller system? Advantages and disadvantages, Chiller’s principle

What is a chiller system?

Chillers are machines that produce cold water to supply the building load. Usually installed for commercial centers, supermarkets, hotels or factories.

A chiller system, also known as a chiller central air conditioning system, is a machine that uses water as a refrigerant to cool objects and food. The convention will be cooled through an evaporator (usually 12 degrees in and out 7 degrees).

This system is commonly used for air conditioning in malls, supermarkets or manufacturing plants.

Structure of the chiller system

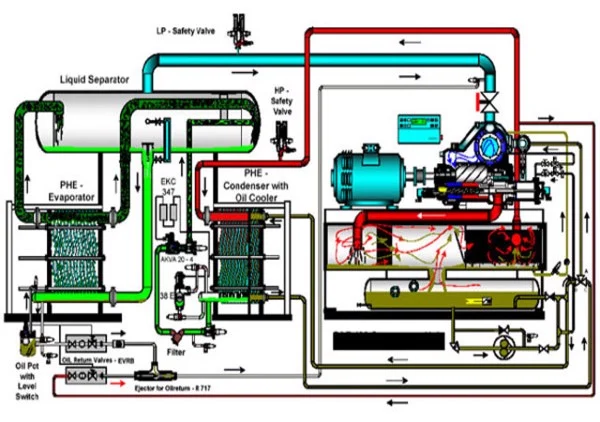

The chiller system – water central air conditioning (Chiller) consists of 5 basic components:

- Water chiller center cluster.

- Chilled water piping system and chilled water pump.

- Load system for direct use: AHU, FCU, PAU, PHE, etc.

- Indirect use load system: air duct system blowing through the room to be air-conditioned and all kinds of adjustment valves

- Pumping and circulating water system through Cooling Tower (if any)

The chiller system is manufactured in non-separable clusters, meeting ARI standards.

Classification of chiller systems by use

The classification of this chiller system is based on many different ways. Typically, these systems are classified based on the use they serve as follows:

- Industrial cooling can be adjusted to a very wide range, from 60ºC down to 30ºC. Often used in negative printing, chemical, mechanical, breweries, etc.

- Air conditioners in commercial centers, supermarkets, bookstores, pharmacies, etc., with a narrower temperature control range from 7-12ºC.

Chiller’s advantages and disadvantages

The advantages and disadvantages of Chiller include:

1. Advantages

- The system works very stable, durable and can be used for a long time.

- Using cold water, so there is no fear of poisoning or accidents due to refrigerant leakage

- Suitable for use in buildings such as hotels, offices, factories with all heights and all architectures, suitable for many large projects.

- Capable of handling air with high cleanliness, meeting all requirements for cleanliness of dirt, impurities, chemicals and odors

- Less maintenance and repair required

2. Disadvantages

- Takes up installation space, due to bulky wind pipes

- Labor cost for construction and installation

- High power consumption

- Need highly technical operator

- Regular maintenance is required for the FCUs

- Electricity cannot be billed separately for individual zones.

The principle of operation of the Chiller

The Chiller system works on the principle of state transformation of water. Water from gaseous condensate to liquid form; liquid solidifies to solid.

In the endothermic process in the system, water is converted from solid to liquid and then to gas. That means using ambient heat, cooling the environment and lowering the temperature. If the opposite happens, the process will be exothermic.

Chiller systems typically apply liquefaction to gas (evaporation of water) to capture ambient heat and cool them: the liquid gas evaporates and captures heat from the water causing the water to cool as required.

In the reverse process: the gas is pressurized, so the gas is cold. When passing through the compressor, the gas in the high-pressure vapor state will be completely cooled to become a liquid in a closed cycle. The system is regulated by automatic valves.

Application of chiller system

Chiller systems are used to cool and dehumidify the air in commercial buildings, apartment buildings, supermarkets, hotels or medium to large companies and organizations.

In addition, the chiller system is also used for controlled cooling, temperature and humidity control in the food processing, beverage, plastic industry, chemical processing, pharmaceutical industries, etc.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E . M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA