You are wishing to use Ball Valve but you do not have much information about the product and do not know well about this product. Don’t worry, all your problems will be solved. In this article, P69 Company will share with customers and help them answer the question what is a ball valve? Structure and parameters of current ball valves.

What is ball valve?

Ball valve is a kind of industrial ball valve. This device is widely used to install plumbing equipment or sewer pipes. This device is used to open and close to start the device and regulate the flow of the liquid flowing in the tube.

In order to be able to operate the valve used with the inner rim as a hollow ball, the device can also be rotated 90 degrees to regulate the flow in the valve.

Currently, ball valve products are widely used in many different fields and production activities. Therefore, when customers have a need to use it, they only need to contact reputable addresses to have the opportunity to own quality products and ensure standards.

Structure of Ball valve

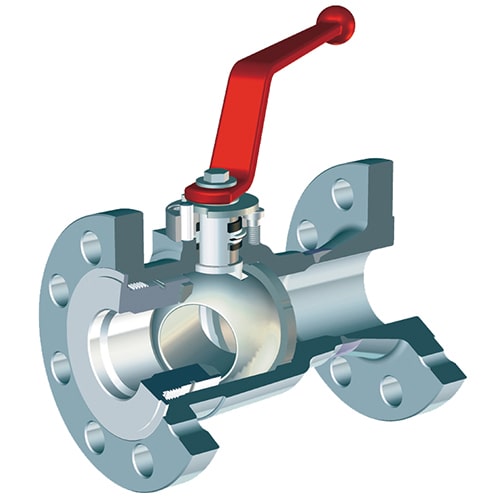

Ball valves are composed of the following main parts:

– Valve body: This is the body part of the valve and the connection part of the valve, they are made from many different materials depending on the specific valve type.

- Material: Forged steel, copper, SUS 304, SUS 316, plastic…

- Connection: Internal thread connection, welded connection, standard flange connection

– Hand lever: The lever part is the part that controls the opening and closing of the valve as well as regulating the flow of the valve. The lever helps to control the valve opening and closing quickly and conveniently. The lever part is usually made of steel, stainless steel with plastic cover to help operate more smoothly.

– Sealing Gaskets: Sealing gaskets are usually made from synthetic rubbers that prevent the valve from leaking. The working temperature of the ball valve depends a lot on this gasket material. Common types of valves usually use PTFE gaskets (working temperature 0 – 110 degrees Celsius).

– Valve shaft: The valve shaft is the moving part controlled from the lever that controls the valve disc to open and close. The valve shaft, because of frequent operation, is usually made of stainless steel and hard metal that is less susceptible to corrosion.

– Ball: Ball valve, also known as valve disc, is the main part that closes and opens the valve door. Usually, the ball valve is made of 304 stainless steel and 316 stainless steel to ensure durability, corrosion resistance and abrasion in the medium. Because the disc is shaped like a ball, they are called a ball valve.

Some common types of ball valves today

Depending on the actual needs, ball valves are produced with many different types such as: 1-piece ball valve, 2-piece ball valve, 3-piece ball valve, 3-way valve, electric control ball valve and pneumatic control ball valve. .

Depending on different types of valves, they will have different specifications. However, the main factors of the valve still include: Material, size, control type, valve connection type, working pressure, working temperature…

Parameters of current ball valves

Basic technical parameter:

– Material: Steel, 304 stainless steel, 201 stainless steel, 316 stainless steel, copper

– Size: DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200

– Connection type: Threaded connection, welded connection, flange connection standard: JIS 10K, BS PN16, DIN PN16, ANSI class 150.

– Working pressure: 10bar, 16bar, 25bar, 40bar, 64bar (Max: 1000bar)

– Working temperature: 110 degrees Celsius (Max: 400 degrees Celsius)

Advantages of ball valve

Ball valves have many outstanding advantages such as:

- High durability, good operation after many valve opening and closing cycles.

- Easy to operate and repair, with high flexibility.

- Working pressure can be up to 1000bar and working temperature can reach 752°F (400°C)

Disadvantages of ball valve

With many outstanding advantages as above, however, ball valves also have many disadvantages such as:

- When the valve is closed, they will trap water in the valve ball bearing (valve disc), when cold temperatures can cause the remaining water to freeze and cause a valve jam. Worse is breaking the valve disc, causing damage to the valve.

- Valve size is relatively small, suitable for small and medium systems.

Application of ball valve

Ball valves are widely used in oil refining; long pipes; chemistry; paper production; medicine; water conservation; electricity; urban; steel and other industries, and occupies an important position in the national economy. It has the effect of rotating 90 degrees, the faucet body is a sphere and has a circle through the hole or channel through its axis.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA