You are in need of using Teflon plastic, but you do not have much information about the product and do not know well about this product. Don’t worry, all your problems will be solved. In this article, P69 company will share with customers and answer the question what is Teflon plastic? Teflon properties, structure and applications

What is Teflon Resin?

Teflon plastic has the English name Poly Tetra Fluorethylene , it is also known by the abbreviation PTFE. With good non-stick ability and heat resistance, Teflon resin is an organic substance containing fluoride. Teflon plastic is one of the new materials born to meet the development of the scientific and technical revolution.

Structure of Teflon plastic

A product made up of many molecules joined together. Tetrafluoroethylene with the molecular formula C2F4 is a colorless, odorless gas produced by heating chlorodifluoromethane (CHClF2) at 600 to 700°C. Chlorodifluoromethane is in turn obtained by reacting hydrogen fluoride (HF) with chloroform (CHCl3).

Tetrafluoroethylene monomers (small, single molecules) are immersed in water and then polymerized (linked into large, multi-unit molecules) under high pressure in the presence of free radicals at initial. The polymer consists of a chain of carbon atoms bonded to two fluorine atoms:

The fluorine atoms surround the carbon chain like a protective shell, creating a chemically inert and relatively dense molecule with very strong carbon-fluorine bonds. The polymer is inert to most chemicals, does not melt below 327°C, and has the lowest coefficient of friction of any known solid.

Teflon plastic properties

Have we understood what Teflon actually is? Here we will continue to help you learn about the superior properties of this polymer.

First, Teflon is highly heat resistant and non-flammable, something very few plastics today can do.

– Teflon has excellent electrical insulation

– Teflon has an extremely small coefficient of friction, only 0.04 is stronger than diamond, so it has good wear resistance.

– Because Teflon does not react with any substances, it is almost not affected by substances with chemical composition, inert to chemical solvents, alkalis…

– Good waterproofing, less aging in harsh climate conditions.

– No change of state, chemical composition in the temperature range of 200 – 260 degrees Celsius.

– Safe for human health when used.

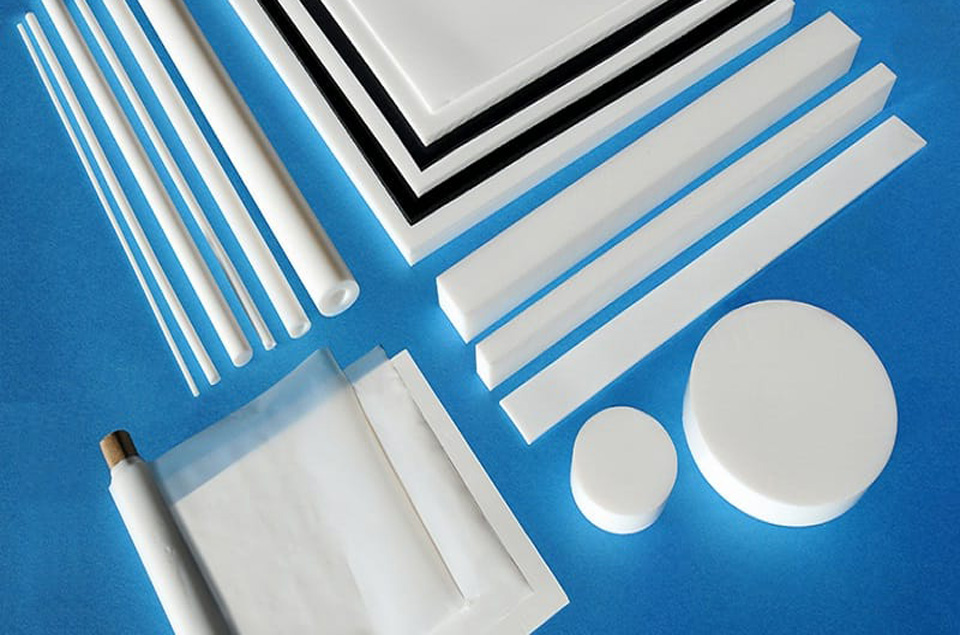

The most popular types of Teflon plastic today

Common types of Teflon resins today include:

1. Teflon plastic sheet

- Is a polymer resin with chemical resistance and extremely low friction surface, no surface adhesion to any materials.

- Teflon sheets are usually milky white with sizes 1mx1m and 1mx10m. Sheet thickness from 5mm to 40mm.

- PTFE sheet is durable, non-conductive, non-flammable and resistant to abrasion. Waterproof, smooth surface makes cleaning easier.

2. Tree-shaped Teflon resin

- Teflon resin has very good thermal stability, the maximum working temperature is +260 degrees Celsius and the minimum is -260 degrees Celsius. This product line possesses outstanding insulating properties, is not moldy, resistant to mold. resistant to chemicals and acids, resistant to ultraviolet rays.

- However, the tree-shaped PTFE resin is quite long, so it is flexible, so care should be taken during transportation and construction. Not only that, its weight is quite heavy compared to some other types of plastic.

3. Tubular Teflon Resin

- The tubular Teflon resin is quite similar to the tree form in terms of its long cylindrical shape. However, because it is a tube, the middle is transparent, so it has a stiffness not equal to that of a tree.

- Thanks to the hollow structure inside, PTFE tubes are very suitable for use in medical devices, insulators, high-performance filters, etc.

4. Film Teflon Resin

- Thin, light and smooth, these are characteristics of Teflon films, which can be rolled up just as easily as conventional plastic films.

- PTFE plastic film is one of the most important insulating materials from organic polymers that has been applied in many fields such as sensors, generators, motors, dosimeters and temperature air filters. high.

Application of Teflon plastic

Thanks to the excellent properties that are heat resistance, electrical insulation, almost no oxygen even in bad environments and safe to use in contact with humans, Teflon’s applications are also extremely wide.

– Teflon is used a lot in the medical, pharmaceutical and food industry… products directly related to human health.

– In the mechanical industry, this plastic is used to replace metal in parts that need high strength, heat resistance and self-lubricating ability.

– For chemical industry Teflon will be used to coat chemical tanks, extremely durable and safe. This polymer is also used to make laboratory equipment to store samples.

– We also see a lot of teflon washers that are lined when connecting flanges together.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA