To install and operate a standard fire pump, how do we need to know about fire pump installation standards? Because after the installation, the fire protection agency will check the entire pipeline system, pressure, and electrical system to ensure safety or not before being licensed to operate. In this article , P69 Company would like to share how to install and operate the most standard fire pump today.

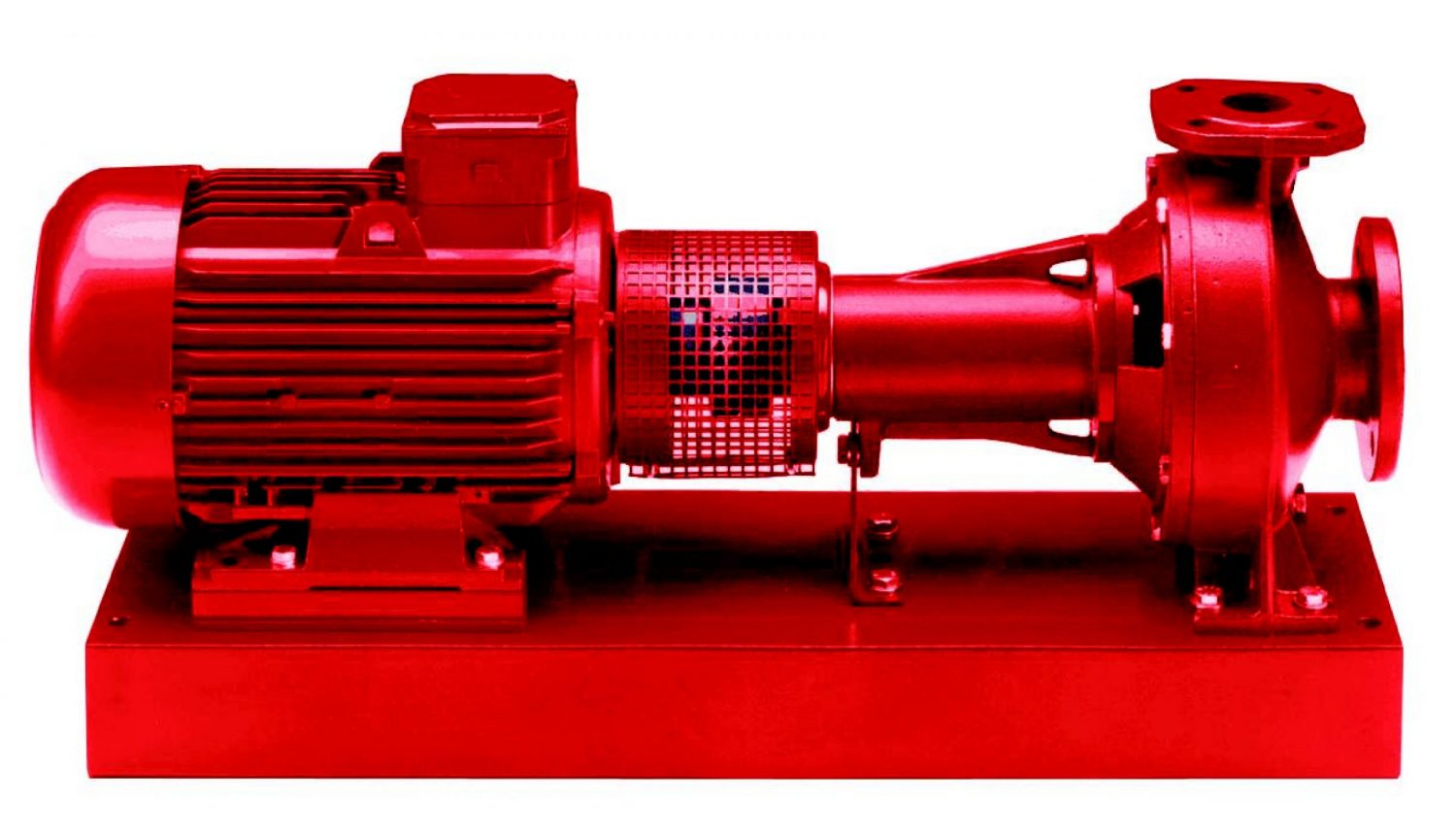

About the fire pump

The fire pump is a centrifugal pump with a large capacity, with a capacity of 10hp, 15 hp, 20hp, depending on the needs of the height to be pumped and the water flow that can be met for pumping water for fire fighting. Fire protection pumps are usually installed in a fixed position, with very large pipelines from 114mm -160mm.

There are two types of fire pumps on the market today:

- The pump is compact, highly portable, and can be transported to many places for use. Example: Pumps mounted on fire trucks. Or portable fire pump..

- The other type of pump is commonly known as a fixed pump station with very high pressure and flow.

For example: Sprinkler system, fire sprinkler system, fire pump system for buildings and structures.

Some notes during the installation of fire pumps

In the construction of fire protection, in parallel with following the manufacturer’s instructions correctly, you should pocket the following notes to help the fire protection system achieve the highest performance:

- While assembling the pipeline, pay attention to the size of the water pipe which must match the pump suction and discharge diameter. Moreover, the connectors must be tight and tight to avoid causing water leakage.

- Pay attention to electrical work to prevent electric shock, fire and explosion.

- Preliminary inspection of the fire protection system before putting it into experimental operation and applying for a certificate of fire prevention and fighting equipment.

The installation of fire protection systems is very complicated, so it requires high technical expertise. Therefore, you should look to reliable units and distributors for the best advice and support. Above all, it is also guaranteed the quality and origin of the product.

Detailed instructions for installation and operation of fire pumps

Proper installation of the fire pump not only increases the life of the pump, but also helps the pump to work efficiently and reduce noise. Today, P69 Company will share with you how to install and operate a fire pump properly

Step 1: Survey the actual scale and area where the fire pump is installed and operated

– Before placing the fire pump, we survey the topography of the pump. The foundation for placing the fire pump should be a hard, solid foundation, limited to wet places, and soft, flexible areas. For soft and flexible areas, it is necessary to lined the stone foundation, coated with cement, to help the foundation to put the pump firmly. It is recommended to build a stand for the pump which will be more secure for the installation of the pump.

– Should the pump background be omitted? Absolutely not, because unlike domestic pumps, fire pumps as well as industrial pumps have a large working capacity. The fire pump motor can generate rotation from 1500 rpm to more than 2500 rpm. With the rotation speed of the motor driving the impeller in the pump, a large vibration will be created. With a long time will lead to damage and reduce the life of the pump.

Step 2: Shipping

– Note when still transferring the fire fighting water pump: When transporting the fire pump, it is necessary to pay attention to the use of cables bearing the minimum load twice the pump’s referee, always use soft materials to line it up. pump wall to prevent the cable from scratching and damaging the pump wall.

Step 3: Choose the pump installation location

– For the installation location of the Diesel fire pump: Install the Diesel pump and choose a location near the fire hydrant so that the pump can absorb water easily.

– The installation location of the Diesel pump must be convenient for use, operation and maintenance during use. Refer to the vent size and spacing.

Step 4: Make the pump base

– The pump pedestal needs to be firm • The base of the diesel fire pump is used with 300 grade concrete with bearing steel inside, in order to ensure its durability and withstand the load in the pump when placed on the pedestal, The size of the pedestal platform depends on the size, the referee of the pump bridge.

– Use bolts to fix the legs of the diesel pump

– Overall dimensions of Diesel pump: L1500 x W760 x H900(mm): use 4 rubber blocks to resist vibration and | Drill holes into the concrete using 4 Hilti expansion bolts HASM 16×120/5/25 to fix the diesel pump legs to the concrete foundation

Step 5: Install the suction pipe and water ejector pipe

– The suction pipe and the water ejector pipe must be installed in the order and position as shown in the figure, including the one-way valve, the water priming pipe, the stop valve, the damper, the suction head must be attached with the garbage filter to prevent trash from the bottom of the lake.

Step 6: Install the machine’s exhaust blower

– The father blows the exhaust gas: Installing a fire pump with the exhaust manifold being arranged towards the outdoors | then at the end of the pipe, a cover must be made to prevent rainwater from entering the machine through the main pipe.

– If the ductwork is arranged in the house where the pump is located, pay attention to the direction of wind blowing and the position of the person standing to control the operation in order to reduce the influence of exhaust gases that affect people negatively during operation. diesel bomb machine.

Note: The connection points on the suction pipe, the ejector pipe must be sealed without leakage and must be pressure tested before connecting to the pump. The location of the water priming pipe must be located in a recognizable position, convenient for regularly checking the pump’s inlet water.

Regulations on installation and operation of fire pumps

From the end of 2020, the design, installation and operation of fire pumps are regulated in Vietnam Standard No. 02/QCVN:2020 . In this set of regulations, regulations on: installation design; operate and test the pump; check and maintain the pump; Fire pump management.

The main contents about fire pumps in terms of design and installation have been mentioned in this article. In addition, you can note a few more things such as:

- For the installation of fire pumps, it is necessary to take backup measures in case the fire pump is damaged, it is necessary to have a fire pump with the main pump capacity as backup.

- The pump motor needs to have protective devices (electrical circuit breakers against overload, thermal relays, …)

- There should be water pressure gauges on the pump pipe.

- Before the water outlet pipe, there should be a one-way water valve to prevent water from flowing back into the pump.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA