Hot-dip galvanized cable ladder is applying technology to coat the entire surface of the cable ladder with a layer of hot-dip zinc to optimally protect the cable ladder against environmental factors, metal corrosion, surface peeling paint… Installing Hot-dip Galvanized Ladder Tray is often applied to outdoor works, near the sea and in places where the environment is highly corrosive…

Let’s immediately refer to the article below with P69 about the installation process of hot-dip galvanized cable ladders. As well as the benefits, features and applications that hot-dip galvanized cable ladders bring.

Outstanding features of hot-dip galvanized cable ladder

In order to make the most accurate choice, users need to know the salient features that hot-dip galvanized cable ladders have as follows:

- This is a product line with low cost but very high efficiency.

- The galvanized layer on the surface of the cable ladder is capable of withstanding many different harsh environments. For example, acidic environment, the environment near the sea or places with a lot of dust…

- The hot-dip temperature of the cable ladder is in the range of 440 – 460 degrees Celsius.

- Cable ladders need to be hot-dipped for a certain amount of time in order for the galvanized layer to have a standard thickness.

- Due to the chemical reaction of hot dipping the product at high temperatures, this line of cable ladders often has a very beautiful pattern.

- Products often have very high durability and have the ability to be widely applied in many separate locations.

Advantages and disadvantages of hot-dip galvanized cable ladder

- Advantages

Open and material-saving design, galvanized cable ladder helps to save optimal costs from material costs, design costs, installation costs and maintenance costs…

Use a cable ladder that can be simply assembled with tools such as pliers, nuts and screwdrivers.

Cable ladders are hot-dip galvanized, durable over time, harsh environments and weather.

- Disadvantages

To promote all the advantages of the powder-coated cable ladder, it is necessary to install the system in accordance with the technical process and design of the project.

Because this material is easily deformed when hot-dipped, it is necessary to take into account the appropriate size and thickness when manufacturing.

Benefits that hot-dip galvanized cable ladders bring

Different from when installing powder-coated cable ladders, hot-dip galvanized cable ladders bring outstanding benefits as follows:

- The reason why hot-dip galvanized cable ladders are increasingly used for electrical cable systems is large because it has the ability to bring very practical benefits to users.

- The product has a very high advantage when it comes to protecting metal surfaces. This is something that not all plating methods on the market can do.

- Perfectly protects metal structures when used in special environments such as industrial gases, marine, acidic environments, etc. It helps to provide long-term durability and absolute safety during use.

- The product has a very high aesthetic value in the works for which it is selected.

- Good bearing feature is also something that users cannot ignore when it comes to this cable ladder. The product can effectively prevent collisions during transportation or installation.

Standard hot-dip galvanized cable ladder installation process

Here is the detailed process of installing powder-coated cable ladders that you can refer to:

1. Step 1: Prepare and check the instrument

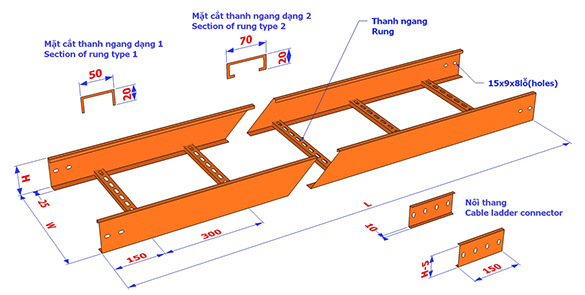

Before installing the hot-dip galvanized cable ladder, you need to prepare all the tools and materials. Not all parts are installed the same, so you need to double-check. Overall, cable ladder kits are the same. Includes ladder, cable frame used for outer sheathing, platform frame, adapter bracket, ground strap and screws, washers and bolts.

2. Step 2: Cut the ladder and base to the right size

If your frame and ladder are the correct size, you don’t need to cut. However, if it is wrong, you need to cut the base and ladder to the right size. Each scale cuts about 2 inches more than the length you want.

3. Step 3: Locate and fix the ladder to the diaphragm wall

You attach the stand to a diaphragm wall or other support point for the cable ladder. Usually, the stand will be attached to the wall or you can drill a hole in the wall of the right size to attach the cable ladder system to the wall.

Then, insert the adapter bracket in the holes on the top of each cable ladder. When doing this, make sure the hook on the adapter frame is facing down, and the cable ladder is up.

4. Step 4: Attach the ladder system support

This operation is quite simple. Currently, ladder frames are designed to simply be pinned to the ladder without mounting. However, you need to make sure the frame is safe to avoid risks during use.

5. Step 5: Hot dipped galvanized cable ladder grounding

This is a major step to prevent electric shock during use. Ladder supports and each sheath must be grounded. You just need to connect the foundation frame to the cable tray at the point near the wall. Then attach the ground strap to the platform frame with a nut. Finally, attach the ground strap to the grounding points on the wall.

6. Step 6: Check the installed cable ladder system

Before putting the cable month into operation, you need to make sure the components are installed according to the standards. Therefore, after completing the installation, please carefully and carefully check the details on the completed ladder system.

Application of hot-dip galvanized cable ladder

Compared to other cable ladders on the market today, hot-dip galvanized cable ladders are known for their wide applicability. With different production characteristics, this cable ladder is the first choice for use in projects located in hot and humid tropical areas. Especially, the product has the ability to be effectively applied in environments near the sea, hot and humid, with a lot of rain, such as the climate of Vietnam.

It can be mentioned that the areas where this line of cable ladders is often preferred today, such as hydroelectric dam door systems, ship hulls, oil and gas rigs, etc. It always makes users satisfied with the efficiency. Outstanding use is available.

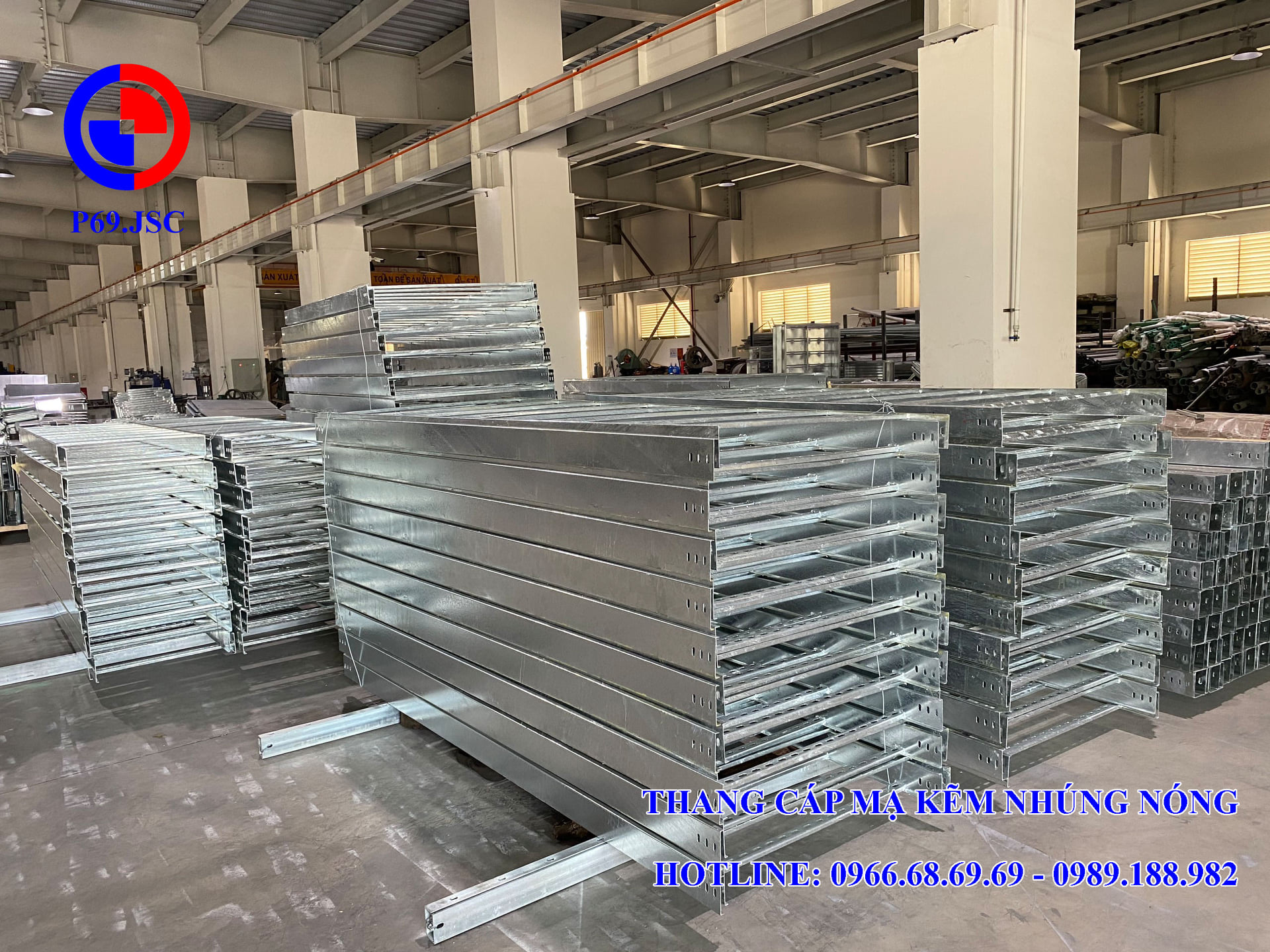

Hot dipped galvanized cable ladder price

Company P69 is an enterprise specializing in providing hot-dip galvanized cable ladders with good quality at favorable prices in the market. Our products not only have good quality but also have remarkably high efficiency when applied in electrical cable systems of large projects. It always makes users happy with what they choose.

Cable ladders are available in different sizes. Depending on the requirements of the buyer used for the project, the price varies. However, the most commonly used sizes of most constructions today are usually:

- Cable ladder size: 60×40; 50×50; 75×50; 100×50; 100×75; 100×100; 150×50; 150×75; 150×100; 200×50; 200×75; 200×100; 250×50; 250×75; 250×100; 300×50; 300×75; 300×100; 400×50; 400×100; 400×150; 500×50; 500×100; 500×150; 600×100; 600×150; 600×200; 800×100; 800×150; 800×200; 1000×100; 1000×150; 1000×200.

- Standard Length: 2.5 – 3.0 Meters

- Thickness: 1.5mm; 2.0mm

Above are the common sizes of hot-dip galvanized cable ladders commonly used in constructions. If you have a request for a monthly quote for hot-dip galvanized cable according to the size above or beyond the size, please contact the phone number 02422121212 – 0965937799.

The reason you should choose the company P69 is a place that provides cheap and quality cable ladders

Along with its dedication and always wanting to bring customers the “Best Value”, P69 Joint Stock Company is always committed to providing genuine products, 100% quality assurance and the best price to customers. in the hands of consumers. With its reputation, P69 always commits the following values to customers:

- Quality is always leading

- Extremely competitive prices

- Always have a very good price for longtime customers

- Commitment to support all questions before and after the sale

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Headquarter: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02422121212 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube: https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA