Transformer is one of the high value products. Users often want cheap or do not have enough money, so they close their eyes to buy doses. But the potential problems and uncertainties when using old transformers (old transformers) greatly affect the use process as well as the maintenance process. Therefore, this article P69 company will help customers who want to buy transformers have a better overview of this type of machine to avoid buying poor quality products as well as notes when installing transformers, installation process put transformer transformer.

What is a transformer?

Transformer or transformer, abbreviated as transformer, is an electrical device that transmits alternating energy or electrical signals between electrical circuits through electromagnetic induction. A transformer consists of a primary winding and one or more secondary windings linked through an electromagnetic field.

A transformer is a static electromagnetic device. They operate on the principle of electromagnetic induction, whose purpose is to convert an alternating current system at one voltage into an alternating current system at another voltage, but the frequency remains the same.

The structure of the transformer

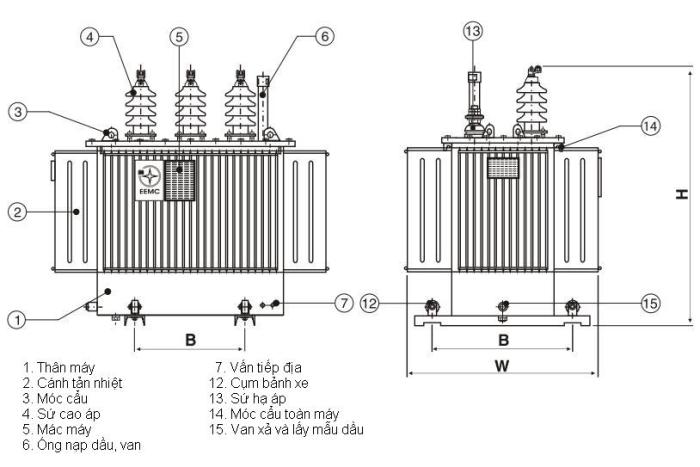

The basic structure of transformers will usually have the following parts:

– Steel core of transformer

– Winding wire of transformer

– Case of transformer

What is a transformer used for?

Transformers are often used to change the voltage of an AC system but not its frequency.

Transformers are often used as a source for some electrical equipment that needs different voltage levels to meet the needs of consumers.

In addition, the machine is also widely used in large power grid systems such as high-tech parks, industrial parks, commercial centers, processing zones…

The transformer can also increase or decrease the voltage, thereby adjusting the voltage level to suit the capacity of electrical equipment, saving electricity consumption costs and prolonging the life of the transformer. service life of electrical equipment.

Conditions for installing transformers in Vietnam

– Individuals and organizations participating in the installation must have professional expertise and understanding of transformers, and must be trained in electrical safety.

– Before connecting the power cable to the transformer, make sure that all the connecting wires are not live (including AC and DC).

– Ensure that before connecting to the grid, the technical parameters of the equipment are suitable and satisfy the regulations of EVN and transmission units.

– The ambient temperature when installing the transformer must be less than 40oC and more than 5oC.

– The maximum height allowed to install the transformer is less than 1000 m;

– The earthquake coefficient is less than 0.1.

– Wind speed in transformer installation environment must be less than 160 Km/h.

– The installation site for oil-cooled transformers must have an oil sump and be fully equipped with fire prevention and fighting equipment.

– The transformer installation ground must be well ventilated, away from heat sources;

– In places where there is a lot of smoke and dust, it is necessary to take measures to prevent and minimize dust from affecting the transformer.

Notes on installing transformers

When installing transformers, it is necessary to pay attention to the following things to ensure stable operation and ensure operator safety.

– Before installing the transformer, it is necessary to pay attention to the power index, the symbol information in the transformer carefully to limit the risks and increase the safety of the transformer.

– Electrical cables used for installation need to have a reasonable slack and not be stretched.

– On the high-voltage side, there must be porcelain to prevent lightning, the high-voltage fuse falls by itself, the machine needs to be grounded.

– On the low-voltage side, it is necessary to have a low-voltage isolator or an Aptomat automatic breaker with suitable rated current.

– Especially for transformers with a capacity of 100KVA or more, it is necessary to have an ampere meter to check how much the load is.

– During the installation and use of transformers, it is advisable to periodically check the transformer currents to make sure they are still in good working order.

Install the transformer

The standard transformer installation process includes the following steps:

1. Step 1: Check when installing transformer

– Radiator fins and transformer cover are not deformed, paint peeling, the drop surface and equipment installed on the transformer cover are clean, free of dust or mold;

– The ceramic connectors are not broken/sharp/batch, do not leak oil on porcelain/porcelain legs. Porcelain ensures clean, dust-free;

– Other devices such as regulator, safety valve, oil level indicator, gas relay (if any), thermometer (if any) are in the correct position and ready to work. All equipment must be clean and free from oil spills;

– The grounding system must be installed according to technical standards.

2. Step 2: Determine the mounting position

-

Indoor installation

– The place where the machine is placed must have a door for cold air to enter (located in the lower part of the machine room) and a hot air outlet (located at the top of the machine room). Ventilation doors must have a system to prevent organisms from entering the living environment (rats, birds, snakes…);

– The hot air outlet should be calculated and constructed with a large enough area to support the heat dissipation of the transformer;

– The distance between the transformer and the wall or between the transformers is at least 0.5 m or more;

– The space where the machine is located must be convenient for the process of checking and maintaining equipment (for example, adding oil, taking oil samples, observing the oil level…);

– The installation ground of the transformer has an inclination of no more than 2 degrees.

-

What are the advantages of indoor transformers?

Transformer is one of the indispensable devices in the efficient use and transmission of electricity. Indoor transformers are one of the types of transformers that many people choose to use today because of the great advantages that it brings:

Optimizing the use of materials and the safety of the user, the machine can be selected from a wide range of possible installation types. This transformer complies with international standards and those intended for the future.

Saving time in research and design, reducing costs, and reducing installation costs is due to the elimination of the need for temporary connections at the start of construction, reliability independent of construction. The main projects. When construction is simplified to the fullest extent, only a foundation made of concrete can withstand the force.

When using a substation, the installation and connection are greatly simplified.

These models are usually compact, aesthetically pleasing and are used in important places such as offices, offices, guest houses, etc.

-

What are the disadvantages of indoor transformers?

The biggest disadvantage of this type of substation is that it is more expensive to build than other types of substations because it requires a larger area to build a substation campus than other types of substations.

-

Outdoor installation

– Transformers can be installed on high ground or on pylons in accordance with manufacturer’s regulations and general technical standards of Vietnam.

– The installation position ensures balance and safety during the time of using and operating the device;

– Around the machine installation area, there must be a barrier fence in accordance with the regulations of the State, ensuring safety during operation and if there is an incident, it will not cause damage to life and property of the users. people around.

-

Advantages of outdoor transformers

The biggest advantage of an outdoor substation is that it transmits a large electrical capacity from the place of production to the place of consumption, increases voltage, limits power loss and reduces costs, and saves investment costs on the line. .

-

Disadvantages of outdoor transformers

When building outdoor substations, there are some disadvantages that can first be seen as unsightly, not suitable for narrow urban areas, mainly serving in factories. , industrial factories or production areas that need large power capacity.

So with the information about the advantages and disadvantages of indoor and outdoor substations that 2DE provides, hopefully, it will help you have a better overview so that you can make the best choice.

3. Step 3: Check before turning on the power

– Level changers and regulators (no-load regulators) must be in a position corresponding to the voltage level used;

– The distance between the two lightning arrestors and the 22 kV transformer is 10 cm and the 35 kV transformer is 14 cm;

– Transformer oil level indicator (with oil cooler): In white, if the oil quantity is sufficient and in red if the oil is lacking. In case of oil shortage, it is necessary to contact the production or installation and maintenance unit;

– Cooling system: With large capacity transformers over 3500 kVA, there is usually a separating valve between the tank shell and the radiator. Before closing the power, the separating valve must be opened to allow the cooling oil to circulate between chassis and radiators;

– Equipment such as pressure protection (safety valve with closed transformer and explosive discharge tube with open transformer), gas relay, and temperature measurement must ensure integrity, free from dust and grease.

– Insulation test: When measuring insulation resistance, if the measured value is less than the parameter according to the machine history, the connecting conductors (including the ground wire) must be checked again with the transformer. Check that these connectors are completely isolated. If the connecting conductors have been isolated, but when checking the resistance value is still less than the parameter according to the machine history, the energizing must stop and notify the manufacturer or distributor for remedial measures.

Contact information P69 – M&E Contractor

Headquarter: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02422121212 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube: https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA