Globe valve or globe valve is a very common valve in steam or gas systems. Today’s article P69 company will introduce to you what is a globe valve? Structure, working principle of globe valve,…

What is Globe Valve?

Globe valve or we also called globe valve. Globe Valve is the English name of the line of globe valves used to regulate the opening and closing of the flow of fluid. The structure of the valve is tilde or spherical in the middle, the two halves are separated by a flow control device inside the valve body.

Basic specifications of globe valve

- Globe valve size: DN15 – DN300

- Valve body material: stainless steel, steel, cast iron, copper

- Connection type: Threaded, Flange, Welded

- Working pressure: PN10, PN16, PN25, PN40, PN63

- Operating temperature: -10ºC – 400ºC

- Flange standard: JIS, DIN, ANSI, BS

- Operation type: Hand crank, electric control, pneumatic control

- Operating medium: Water, compressed air, hot steam, hot oil, chemicals

- Origin: Taiwan, Korea, China, Europe

Here are some basic information about the specifications of the globe valve. For each type of globe valve or manufacturer, the details may vary slightly. In general, the general parameters of globe valves meet this standard.

Structure of Globe valve

In general, globe valves have a relatively similar structure in internal details. Only a few small details differ according to the manufacturer and the type of glove valve used. Let’s go through its structure in detail

1. Body globe valve(Body valve)

The body is the main part of the valve, it contains all the remaining details of the valve body. The valve body is shaped like a tilde, which sometimes looks like a saddle, so people often call it with such names.

The valve body is molded monolithically from materials such as cast iron, steel, stainless steel, copper and sometimes also plastic. It can be double-flanged to connect to pipes (this is the main form) or can also use threaded, welded connections to connect to pipes.

2. Disc (Disc)

The valve disc is the part inside the valve body. This is the part used to open and close to regulate the fluid passing through the valve. Valve discs come in many shapes depending on the manufacturer. The valve disc can move linearly up and down the valve shaft, one end is fixed to the valve shaft, when the disc is closed it will squeeze the disc face into the valve seat and completely seal the fluid passing through.

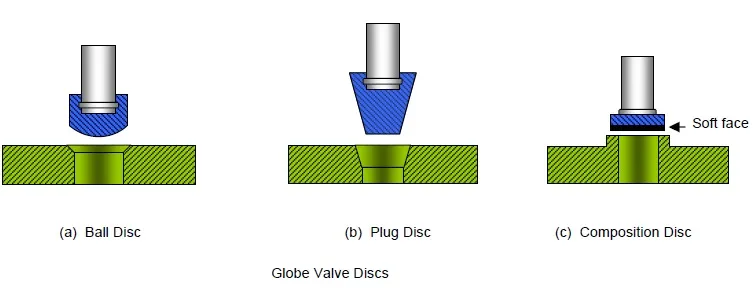

There are three main types of globe valve discs available today

- Ball disc: Means the contact end of the disc and with a ball-shaped cushion, this is a disc valve suitable for applications with low pressure and temperature, suitable for the need for full opening and closing rather than for regulation

- Composite valve disc (Flat disc): This disc is flat, when closed it is perpendicular to the valve cushion. For this line of valve discs, mainly corrosion-resistant metal materials are used, so it can work well in high temperature and pressure environments. Suitable for use with hot steam systems

- Plug Disc ( Plug Disc) : Also known as cork, latch disc, shaped like a cork. With the valve cushion contact head is made smaller and cylindrical elongated. This type of disc valve is very suitable for regulating flow through.

3. Valve cap(Bonnet)

The valve cover is the part located on the valve body that is connected to the valve body through bolts. The valve cover is not only responsible for protecting internal components such as the valve shaft, the valve disc, it also has another task of disassembling for cleaning maintenance or combining to form a solid structure for a stable valve shaft.

4. Valve shaft(Stem)

The valve shaft is responsible for connecting the valve disc and the handwheel. It is a long round cylindrical metal rod. The upper end is threaded according to the thread pitch standards of each manufacturer, the lower part is fastened to the valve disc

The valve shaft moves in a circular motion and reciprocates up and down so that the valve disc can be raised and lowered in the form of closing, opening or regulating flow

5. Valve actuator

The most common valve actuator today is the handwheel. It is the most common form with the shape of a car’s steering wheel. Can move left or right to open and close the valve

Currently, the transmission part of the valve is also used by electric motors, pneumatic motors to replace the steering wheel to control the valve. People often call it electric control globe valve or pneumatic control globe valve

6. Sealing gasket

In addition to the main parts above, the globe valve also has an additional sealing ring to ensure the tightness between valve parts such as valve disc, valve cap, and valve shaft.

The use of gaskets according to which material depends on each line of globe valve. The most common and popular are lead (Graphite), NBR, PTFE…

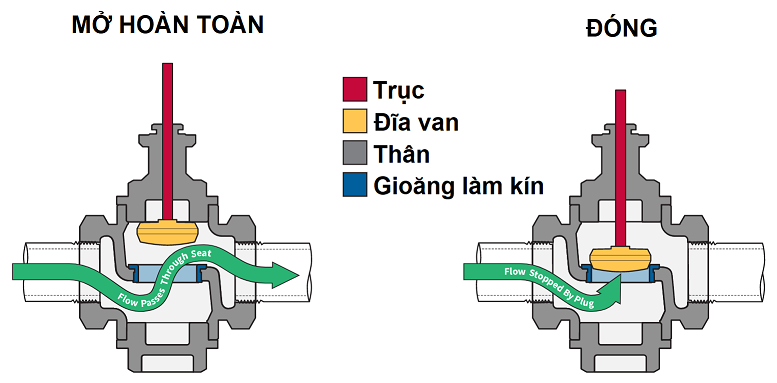

Working principle of globe valve

Globe valve – Globe valve can be used to regulate the opening and closing linearly from 0 to 100% or fully open. Used for installation and use in environments: superheated steam, saturated steam, liquid gas, vacuum, frozen environment The handwheel controls the valve shaft to rotate around the valve body, pulling the valve disc up and down. , ant the valve opens and closes.

The water flow through the valve will swirl upwards, so the pressure of the back flow through the valve will be consumed and cause a pressure drop. With the same structure and operating mechanism as on the globe valve, it has the ability to throttle the flow better than the gate valve. In addition, they are less likely to leak than other industrial valves.

What is the advantage of globe valve?

- Globe valve has the ability to regulate flow very well, high accuracy

- Globe valves have high durability, less wear, and damage due to the fact that when the valve is fully opened, the valve disc is isolated from the fluid.

- Quick valve opening and closing time, due to shorter stroke than gate valve

- The valve opening time is fast, the impact force to open the valve is small

What are the disadvantages of globe valve?

- The pressure of the fluid flowing through the valve is much reduced compared to the original

- Due to the effect of fluid pressure on the valve disc, closing the valve in large size valves requires more force

- Weight and size are usually larger than other valves of the same size

- Relatively high cost compared to other industrial valves

Application of Globe valve

– Use globe vale for applications designed to regulate: clean water systems, oil systems, hot steam, hot water, high pressure compressed air can all use globe valves

– Used for fuel oil systems: Globe valves can be used to precisely regulate the fuel flow or close to prevent fuel leakage causing waste and pollution to the environment.

– Use in hot steam system: This is the main application of globe vale: Any heating system needs to use globe vale from used to regulate to open and close the passing heat. Using the globe valve as a water supply valve to the furnace, the globe vale is used to separate the condensate from the system…

– Application for turbine lubrication system: Globe vale is the preferred valve line for these applications because turbines require constant lubrication and operate in high pressure and temperature environments where priority is to be given to flow. Precision valves for the most throttling and long-lasting performance

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA