In automation control systems, we often hear about linear valves or linear control valves. So what is a linear valve? Structure, application, working principle? Today P69 company will share with customers and help customers answer the above question.

Linear control valve is a valve that is automatically controlled by the signal linear 4-20mA or 0-10V with the task of adjusting and regulating the flow of large and small as desired. Linear control valve is also known as linear valve using linear control head that can be installed for industrial valves such as ball valve, butterfly valve, globe valve, gate valve, good for many equipment systems, fluid environment of water, gas, vapor, solution, and chemicals suitable for many fields today.

Linear valve or regulating valve can open and close the valve in many different angles such as 10, 15, 20, 40, 45, 60, 90,… degrees depending on the system operation that can be easily adjusted angle of flow thanks to the linear valve. Linear control valve we are imported genuine from many big countries with the best quality and cheapest price on the market today.

Linear control valve specifications

- Valve sizes: DN15, DN20, DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300,… DN1000.

- Valve body type: ball valve, butterfly valve, globe valve, gate valve, knife valve

- Valve material: stainless steel, cast iron, plastic, steel, copper

- Control type: pneumatic control, electric control

- Mounting type: threaded, flanged, butterfly valve (wafer, lug), welded…

- Flange valve standards: JIS10k, BS, DIN, ANSI,…

- Signal: 4-20mA, 0 – 10V

- Opening and closing: 10, 15, 20, 40, 45, 60, 90,… degrees

- Electrical control: 24V, 220V

- Pneumatic head: 0 – 8bar

- Working temperature: – 5 degrees Celsius to 300 degrees Celsius

- Working pressure: PN10, PN16, PN25, PN40

- Working medium: water, gas, vapor, solution, chemical, fluid,…

- Origin: Taiwan, Korea, China, Japan, Europe

- Warranty 12 months

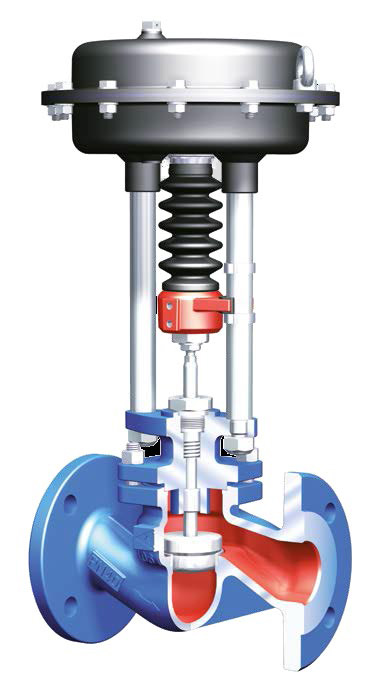

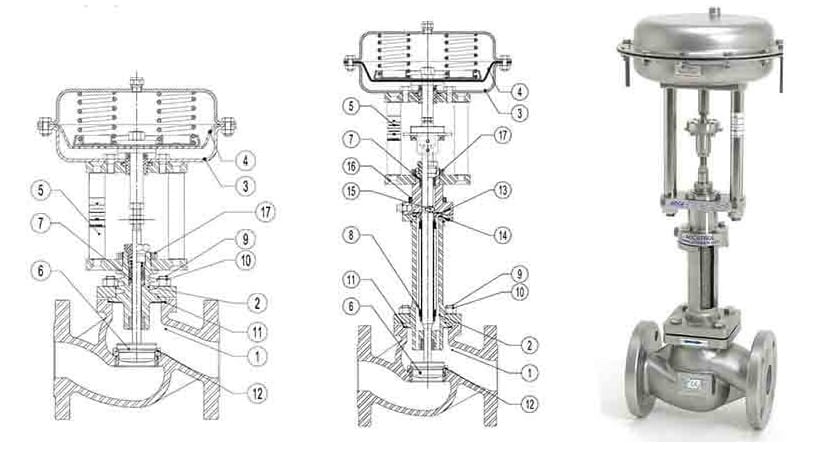

Structure of a linear valve

Like other control valves, the linear valve has two separate components that are put together: the actuator and the valve body.

1. Linear actuators and controllers

The actuator here is a crazy motor or a set of pneumatic cylinders. They are used to transmit torque to the vavle shaft that helps the valve operate.

As for the electric actuator, it is integrated with a 4~20 mhA or 0~10V signal processor. For pneumatic actuators for linear control, it is necessary to add a pneumatic regulator (Posittioner) to regulate the compressed air to help the valve open and close at an angle.

This regulator is also controlled by a pulse signal of 4~20 mhA. It is responsible for regulating the airflow, so that it is just enough to open and close according to the preset angle.

2. Valve body parts

These are popular industrial valves such as ball valves, butterfly valves, gate valves, globe valves. All industrial valves can be used for linear control. However, if you want the most accurate adjustment, we should use a globe valve. Since the globe valve does not need a linear controller, it can be adjusted very well by itself.

Application of linear valve

There are many applications where flow control valves are needed. Some typical applications are as follows:

– Pressure control: At this time, the pneumatic linear control valve becomes a pressure regulator. With this function, we can be satisfied with the pneumatic valve for this application because of its accuracy and responsiveness.

– Temperature control: Likewise, the pneumatic linear control valve runs the function for the temperature control valve with very high accuracy.\

– Flow control: To open and close the flow of a metering system with maintainability and linearity, the pneumatic linear valve is the perfect choice.

These are 3 very common applications of pressure control valves.

Advantages of linear valve

- Linear valves have advantages are automatically controlled without effort like mechanical valves.

- Linear valve can be used to open and close in many angles, used to regulate the fluid flow in the system.

- Linear valve can be used to install a variety of industrial valves such as butterfly valves, ball valves, globe valves, gate valves, knife valves.

- Linear valve can connect to the electrical cabinet and transmit the valve operation signal to the electrical cabinet system, making it easy to control the valve operation.

- Linear valve withstands high heat, high pressure, works well in many fluids, water, gas, steam, solutions, chemicals.

- Linear valve easy to install, use, service and maintain the valve.

- Linear valve has high quality, good price and is warranted by us for 12 months.

- Linear valves have a variety of origins, are imported genuine from many big countries China, Taiwan, Korea, Japan, Europe.

The most popular types of linear valves today

Some of the more popular types of linear valves today include:

1. Linear Control Pneumatic Valve

For linear control at the pneumatic valve, we need the help of a positioner regulator. The air line will enter the pneumatic regulator, the regulator receives the control pulse signal. Then, based on the opening and closing status of the valve, it will regulate the gas flow so that it opens to the required angle.

Note, the regulator only uses compressed air pressure from 3-8 bar. Therefore, if the compressed air pressure is high, it is necessary to reduce the pressure before entering the pneumatic regulator.

Pneumatic valve linear control is a stable and safe operation valve line. The valve opens and closes quickly, suitable for situations where quick changes are required. The disadvantage of the valve is that when operating, it generates a loud noise.

2. Linear control solenoid valve

Unlike pneumatic valves, electric linear actuators have built-in pulse signal receivers. The linear electric actuator has a built-in control signal receiver. It also has an LCD screen to display the percentage of the valve opening and closing, which is very convenient. In addition, direct on-site control is possible thanks to the control keys integrated on the body of the electric actuator.

The solenoid linear control valve has much higher accuracy than the pneumatic control valve series. Because it is integrated two in one, it has another advantage that is compact. With modern controllers, it is also integrated with overload protection. This helps the valve stop working when there is a problem or a hard object gets in the way.

The disadvantage of this valve line is that it is much more expensive than compressed air. Its opening and closing time is also much longer than that of pneumatic valves.

Working principle of linear valve

In terms of operating principle, all types of automatic valves or linear valves share the same operating mechanism and are mainly based on actuators, also known as agitators.

What role does the exciter play in the operating principle of the control valve?

The actuators of all industrial valves are now divided into two types: pneumatic actuators and electric actuators. With two names, we can also easily identify the actuator’s motion structure, which is pneumatic and electric. This is the different part of these 2 actuators. The rest will be pretty much the same.

The Actuator also has a moving gearbox that helps to change the torque and speed of the engine or compressed air and converts from circular motion to linear motion to help open and close the valve.

The working principle of electric control valve or pneumatic control valve is very simple. The valve is opened and closed completely automatically thanks to the actuator. In order for the actuator to understand and act for the valve to open or close, it is necessary to have an additional board to recognize the linear signal or on/off from the control device.

Above is the basic part of the operating principle of the control valve. Hopefully the article will be helpful for you in learning about your automatic control valves .

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline : 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA