Complying with standards for copper pipes when installing air conditioners will help the machine operate more stably and safely. Learn about copper pipe standards when installing air conditioners and air conditioners with P69 in the following article!

Why must standard copper pipes be installed?

Installing the right air conditioner copper pipe is very important to help the copper pipe increase its durability, and at the same time help the air conditioner operate stably, providing optimal cooling and heating efficiency. On the contrary, if you use non-standard copper pipes, it can cause some problems such as:

- Causing the air conditioner to not cool or heat, and cause it to run incorrectly.

- Using the wrong refrigerant copper pipe can also cause the pipe to crack, leak gas, shrink the pipe or change the gas flow very dangerously.

Therefore, the correct installation of copper pipes is extremely important.

Copper pipe standards when installing air conditioners you need to know

Copper tube is a very important part for every air conditioner. Not only related to the efficiency in operation, but the selection of copper pipes for air conditioning also determines the life of the equipment… When installing air conditioners, you need to choose copper pipes based on the following criteria:

1. Copper tube size

Copper pipes for air conditioners are mainly:

– 10mm copper tube for 1 HP air conditioner (~9000 BTU).

– 10mm or 12mm outer diameter copper tube for 1.5 HP air conditioner (~12000 BTU).

– 12mm outer diameter copper tube for 2 HP air conditioner (~18000 BTU).

– 12mm or 16mm outer diameter copper tube for 2.5 HP air conditioner (~ 24000 BTU).

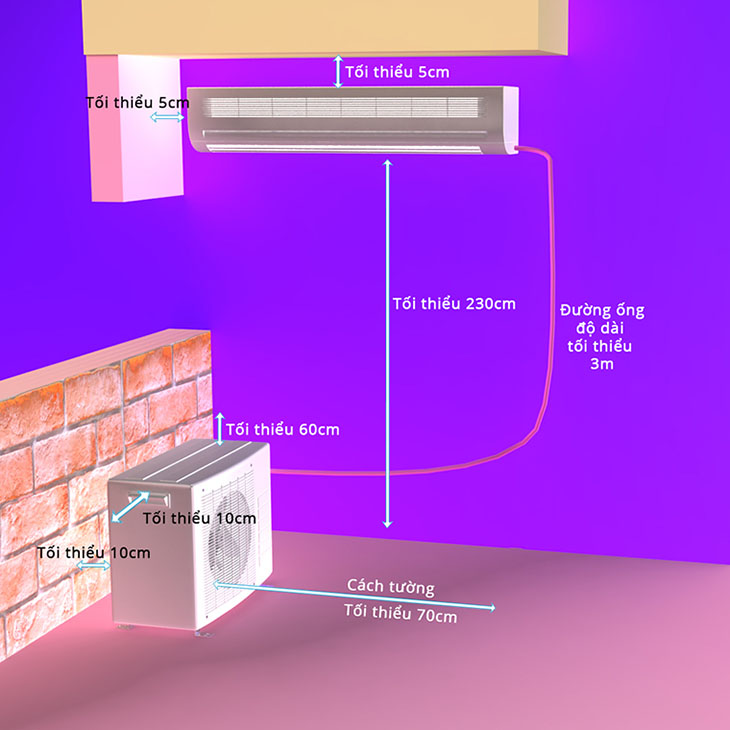

2. Length of copper pipe connecting outdoor unit and indoor unit

Similar to the copper pipe size, the length of copper pipe connecting the outdoor unit and the indoor unit must also comply with the installation requirements specified by the manufacturer.

If the copper pipe is installed too short, it will happen that the solvent/gas cannot be returned to the compressor in time and become blocked, causing serious damage. If the copper pipe is too long, it will cause the air conditioner to cool slowly or not cool at all. And outside the specified length limit of the machine, the manufacturer will refuse to warranty the product.

Each brand, each model has a different length of copper pipe installation (usually the minimum length is about 3m , the maximum is about 15m or 20m for those with large capacity) and usually the average length for the machine to work. the best range from 3-7m . Specific information about the distance for each machine, you can see in the specifications section of each product.

3. Height difference between outdoor and indoor units

In addition to the length of copper pipes to connect the outdoor and indoor units, you should also pay attention to the difference in height of the outdoor and indoor units. This height difference must also be within the allowable limits of the manufacturer and depends on the length of the copper pipe.

In fact, the height between the outdoor unit and the indoor unit does not affect much because most users often install the hot and cold units on the same floor in the house. This parameter will be important for high-rise buildings, buildings, apartments, …

Refer to the size of copper pipes for air conditioners of some brands

Below are the air conditioner gas pipe sizes of a few brands for your reference.

| Air conditioner series | Inverter | Non-Inverter |

| Toshiba | Model N3KCV: 1.0HP using 6/10 1.5HP tube using 6/10 2.0HP using 6/12.7 tube |

Model N3KPX: 1.0HP using 6/10 1.5HP tube using 6/12.7 2.0HP using 6/12.7 tube |

| Daikin | Model FTKS: 1.0HP using tube 6/10 1.5HP using tube 6/10 2.0HP using tube 6/12.7 Inverter Gas 22: FTKD FTKD25 6/10 FTKD35 6/12 FTKD50 6/12 |

Model FTE: 1.0HP using 6/10 1.5HP tube using 6/12.7 2.0HP using 6/16 . tube |

| Panasonic | Model TS: 1.0HP using 6/10 1.5HP hose using 6/12.7 2.0HP using 6/12.7 hose (for MNP code). Date 2014 Q code using 6/16 . tube |

Model KC/C: 1.0HP using 6/10 1.5HP tube using 6/12.7 2.0HP using 6/12.7 tube. Particularly for model 2.0HP date 2014 with tail code QKH using 6/16 . pipe |

| Sharp | 1 HP using 6/10 tube 1.5HP using 6/12 . tube |

1 HP using 6/10

1.5HP tube using 6/12 tube 2HP using 6/12 . tube |

| Fujitsu/General | 1.0HP using 6/10 1.5HP hose 6/10 2.0HP using 6/12.7 . tube |

1.0HP using 6/10

1.5HP hose 6/12.7 2.0HP using 6/12.7 . tube |

How to fix too long pipe?

The maximum pipe length for wall mounted machines with a capacity of 9000btu – 12000btu is usually 15m. In case the air conditioner is installed in excess of 7m, it can be overcome by adding a small amount of gas to the system, usually 20g/m2 exceeds the allowable limit.

The pipe length is too short, we will be different by extending the pipe according to the manufacturer’s technical standards recommended by the manufacturer.

Besides, when installing air-conditioner copper pipes with a capacity of more than 9000btu-12000btu, the pipe length also has many changes according to the manufacturer’s standard system. Currently, manufacturers also launch many models of air conditioners that allow extending pipes to meet the needs of buyers who do not have convenient space for installing air conditioners.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02422121212 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA