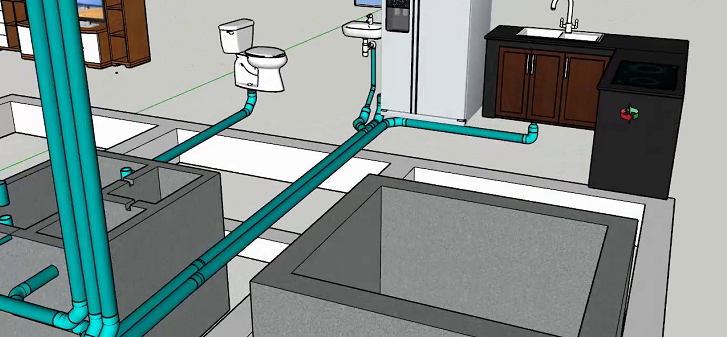

Sealing test of water supply and drainage pipes is a particularly important task of the acceptance and installation of drainage systems. In case the drainage system leaks, it will lead to subsidence of the ground; seepage; dispersing odors;… Therefore, in addition to pressure testing of water supply pipes , the criteria for checking the tightness of drainage pipes with water always need to be closely monitored.

The article below Company P69 will introduce you to the standard water supply and drainage pipe sealing test process from A – Z.

Requirement of sealing test of water supply and drainage pipes

– Before having the requirement to check the tightness for a section of culvert, the parties must ensure that the culvert route must be constructed in accordance with the construction quality control process and specific design requirements:

+ All input materials must meet design standards, especially the quality of drains and rubber gaskets;

+ The joints must be maintained according to the construction process;

– The number of culverts to be inspected is decided by the Investor: All of them can be tested on the whole route or by probability.

Preliminary check when testing the sealing of water supply and drainage pipes

– Check for ventilation and flatness. Make sure there are no foreign objects in each pipe between the two manholes with the naked eye, with lights illuminating both ends of the pipe. If a foreign object is detected: soil and rock; tool; or the local reverse slope (due to settlement and broken pipes) must be treated to achieve a flat ventilation according to the design.

– Select any number of different pipe segments for each sewer line (each section is about 65m in length, with 1 manhole in the middle of the route and 2 manholes at both ends). Pour water into the manhole upstream with a flow that ensures the fullness of the water in the pipe h ≥ D/3. Drop a plastic ball d ≥ 100, if the ball follows the flowing water with a velocity v ≥ 0.3 m/s, it is satisfactory.

Instructions for testing the tightness of water supply and drainage pipes

When the culvert meets the paint test, the tightness of the system will be checked according to the following steps:

Step 1: Select the segment to try

A section of sewers and manholes bounded by three successive manholes.

Step 2: Isolate the pipe to be tested

– Isolate by sealing the inlet and outlet pipes at the manholes at both ends of the test section;

– Pour water into the upper manhole until the manhole overflow is low, soak the pipe for 60 minutes to ensure that the gas in the pipe has been exhausted and the system is stable. It is necessary to cover manholes to avoid evaporation of water;

– Then add full water to the original position, then mark the water level on the high manhole wall and monitor for not less than 30 minutes.

Step 3: Evaluate the results

If the water level loss is within the following limits, the requirements are met.

|

Drain diameter

|

Water loss in 30 minutes/m

|

| 300 | 0.54 liters |

| 400 | 0.67 liters |

| 500 | 0.83 liters |

| 600 | 1.03 liters |

| 800 | 1.28 liters |

| 1000 | 1.59 liters |

Step 4: Record the assessment results in the diary or minutes

Step 5: Continue checking for selected routes

Specific sealing test procedure for water supply and drainage pipes

Please refer to the specific water supply and drainage pipe sealing test procedure with the following drainage pipes.

1. For rain pipes

Construction of the roof down to the basement to the drainage manhole outside the house.

– Every 3 floors, use the lid and glue to fix it. Place the rubber ball in the inflated riser pipe. Then fill the pipe with water. Within 10 minutes, if there is no water leakage, the pipe defects are not abnormal, it is satisfactory. Leaky pipelines, joints with abnormal phenomena must be overcome, thoroughly treated, and then re-tested.

2. For domestic water drainage pipes:

When the construction is completed 1 floor, check all connection points; great hanging; shelf; Check if the tube plug is secure. If you have made sure, fill the main shaft with water and leave it for 10 minutes. Then check again if no water leakage is satisfactory.

If the pipe has an abnormal phenomenon, we must fix it, repair it immediately and then test it again.

3. Collaborative testing of Wavin-AS sound-reducing drainage pipes:

– Try each floor one by one.

– The pipe is fixed firmly by the belt, threaded, not displaced when discharging water into the pipe.

– At the end points of the pipeline, use the company’s specialized seals & cuffs to fix the plugs.

– Pump water into the pipe until the water is full to the floor of the angler floor. Within 10 minutes, if there is no water leakage, the pipe defects are not abnormal, it is satisfactory. Leaky pipelines, joints with abnormal phenomena must be overcome, thoroughly treated, and then re-tested. Check and fix leaks if any.

Regulations on sealing test pipes for wastewater and rainwater

– Drainage branch pipes placed in the ground or in floor grooves are hydraulically tested before filling them by filling them with water to the core of the floor of the first floor. The pipes placed in the ceiling and In rectangular corridors, fill with water to floor height.

– Test the indoor stormwater network by filling it with water to the highest level of the rainwater collection funnel.

– The test time is 10 minutes and no leakage is allowed.

Evaluation of the pipeline sealing test process

Tightness of joints and leaks is determined by looking at the outside of the joints and by the water level during the pipeline test.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA