To meet the needs of fully equipping your home with electrical equipment while still ensuring safety, here are the experiences as well as the standard construction methods of underground electrical pipes that P69 company divides : share to ensure electrical safety for the community of each of our families.

Factors when constructing underground electric pipes you need to know

This method also requires plastic pipes for electrical wiring, but the pipes will be placed in the wall, in the ceiling or in the floor. The power cord is threaded in a smooth conduit when going straight and through a chicken intestine when turning. This is a way of wiring to ensure aesthetics and save space for the house, avoid the impact of external factors, and ensure the durability of the electrical wiring.

Besides the above advantages, this way of wiring also has some limitations to note: it is necessary to have a design diagram of the wiring network before starting construction; Wires are installed in walls and ceilings, so construction costs are high and when there is a problem, the repair and replacement of the line is difficult and complicated.

Regulations on construction of underground electric pipes

_ Must refer to the drawing before proceeding to install the wiring.

_ When wiring in the ceiling must carefully calculate the lines arranged. Usually these lines are light lines and telephone cables, fire alarm wires, smoke alarms or internet cables supplied to rooms and floors.

Construction of construction works in Ho Chi Minh City

_ For underground wiring: When performing, it is necessary to avoid punching too many unnecessary pipes because it will affect the structure of the building.

_ If the floor has been poured with concrete, only 1 pipe is allowed

_ When constructing, if the pipes encounter the beams, absolutely do not punch the pipes through the beams, but have to find a way to go around the beams or pipes.

_ In 1 day, how many pipelines can be constructed, must report back to the management staff and mark on the drawing to determine the construction progress.

· For light lines: Pull 3 wires with 3 separate colors

_ All use 1.5mm CV single wire and must read the lamp layout drawing to know where to pull the wire and the length of wire to use.

_ Red is L phase, blue is N phase, yellow and green is PE wire (Te wire)

_ A room usually has 3 lines of lights to the corresponding reversing switches. These lines will control can lights, chute lights, decorative chandeliers or frog eyes lights.

· For socket lines: Pull 3 wires 3 separate colors

_ Use 3.0mm or 2.5mm CV wire.

_ White or black color is female wire

_ Striped yellow or blue stripe is PE

_ The rest is the wire

Specifications of conduit for ceiling, wall and floor:

_ The laying of pipes must be done before the builder proceeds with their next step of pouring the floor, laying tiles or firing plasterboard for the ceiling.

_ The wiring pipes are usually PVC pipes Ǿ 20mm PVC Ǿ 25mm or chicken intestine pipes.

The method of construction of underground electric pipes in accordance with safety standards

The method of construction of underground electrical pipes in accordance with safety standards includes the following steps:

1. Making construction drawings

– Based on the basic design drawings and the actual survey at the site, the contractor makes construction and installation drawings.

– Construction drawings approved by the PMU, the supervision consultant.

– After the drawing is approved, the contractor will check the construction drawing and take apart the volume of materials to be used.

– The supervisory engineer assigns all approved drawings to the construction team leader, together to study and come up with the most optimal construction plan.

2. Prepare materials

– Based on the detailed construction progress to estimate materials for each stage.

– Making a warehouse to gather construction materials.

– Complete material approval documents.

– Prepare the list and quantity of materials according to the detailed construction schedule.

– Order according to the approved category.

– Gather materials to the necessary construction site or site.

– Invite the representative of the investor to test and accept input materials.

– Proceed to import warehouse.

3. Construction site

– The construction team leader carefully survey the site, working conditions, power source, temporary water for the working process. At the same time, the organization combines other units without affecting each other.

– The working location must ensure safety before the construction can be carried out, if unsatisfactory, the team leader shall notify the supervisory engineer for solutions.

4. Manpower arrangement

– Manpower is arranged depending on the detailed construction progress.

– Construction workers for conduit for light electricity are divided into teams and groups.

For example, a typical team is as follows: (It is possible to construct 5 units/floor at the same time)

Each team has 20-25 people.

Each group of 2-3 people

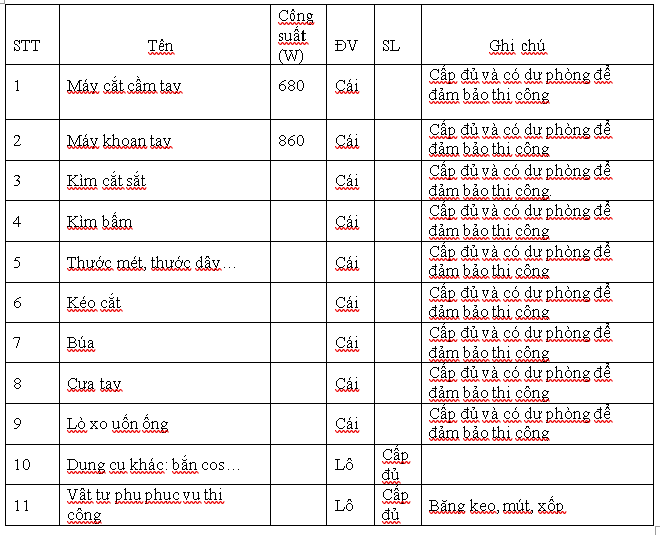

5. Prepare full construction tools

6. Construction solutions

– Work order:

| STT | Job | Contractors |

| first | Processing construction materials and installing underground PVC electrical conduit: The junction boxes are sealed with glue to avoid the situation when pouring concrete. | Electromechanical |

| 2 | Joining the product formwork | Build |

| 3 | Construction Determine to take oil of electrical equipment on the product according to the center of the shaft and beam.

Device location is marked with paint |

Electromechanical |

| 4 | Transport materials to the product to be constructed according to the calculated volume according to the approved construction drawings. | Electromechanical |

| 5 | Knitting, tying steel grade 1 | Build |

| 6 | Construction and installation of PVC conduit and junction box,

Bending pipes with springs of the right type and diameter of pipes Place the spring in the correct position where the pipe needs to be bent to avoid the condition of the pipe being flattened or broken At locations where there are many bends and pipes with a length of more than 8m, add a junction box to ensure Bend one end of the tube, measure, cut, glue the end of the tube and attach the tube to the divider box. The joints must be fastened and the neck firmly fixed to the steel layer 1. Fix the splitter box located below the steel layer 1 at the determined position so that the splitter box is not warped or floating compared to the floor formwork. When constructing pipelines that are carried up to the property or transported to the ceiling to connect pipes to electrical cabinets, switches, sockets…) the ends of pipes will be connected by smooth joints, covered with foam and wrapped with adhesive tape. sure to facilitate connection Particularly for the pipe ends placed on the floor, they will be sealed with a soft plastic pipe and submerged in the concrete 2cm and the floating part is 7-8cm, then the pipe ends will be sealed. Waiting positions will be marked with paint. color to make it easy to see that these positions will be between the partition walls). The pipeline must be fixed to the iron frame by a zinc wire, insert an additional iron frame at the necessary positions, the pipe joints must be glued carefully, for the straight pipe line, the steel wire must be tied at least every other time. about 0.8. The pipes must have a minimum spacing of 50mm for the concrete to see in. Pipes should not go too close to sleeve sleeves: Acoustic box must be filled with foam box, and surface sealed with tape. The pipes are firmly fixed on the steel layer The ends of the underground pipe going up must be bent 90 degrees and the end of the down end is positioned with steel wire. |

Electromechanical |

| 7 | Internal testing of the construction and installation of underground PVC pipes according to the approved construction drawings. Check the location and size of the equipment Check the path of the wires and the size of the diameter of the pipelines. “Check the pipe bends (not bent, not beautiful, broken…) |

Electromechanical |

| 8 | Collect self-dropped objects, clean up, return the construction site to the construction contractor. | Electromechanical |

| 9 | Invite the Investor and the Supervisory Board to conduct the acceptance test according to the approved construction drawings. | Electromechanical |

| ten | Handover ground |

M&E – Construction

|

| 11 | Construction supervision of floor concreting: “The contractor arranges 1-2 experienced workers to supervise and repair when the construction contractor carries out the construction of concrete floors to avoid the situation when constructing machinery. and recognize construction damage and displacement of pipes and junction boxes waiting for equipment. |

Electromechanical |

Contact us today for a free consultation and answer at:

Contact information P69 – M&E . M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA