Installing a water pump with proper technique and convenience is not too difficult but not easy. Especially when we have no knowledge about pumps. Demand for pumps is increasing day by day. So what is the structure of the water pump? How to install the water pump? What are the precautions when installing the water pump? Please refer to the article below with P69 company .

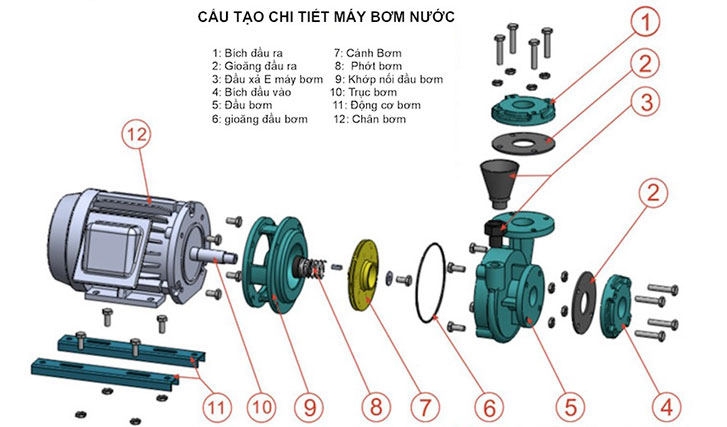

Structure of the water pump

Consists of 4 main parts:

- Propeller: Includes fully open blades, partially open blades and fully enclosed blades.

- Pump shaft: Usually made of high-strength stainless steel, fitted with the impeller through a key joint.

- Navigation part.

- The spiral chamber, also known as the outlet unit: has a relatively complex shape and is usually cast in cast iron.

There is also another type of analysis that is the water pump is composed of two main parts: the pump head and the electric motor.

- Pump head: Usually made of metal, usually copper or stainless steel, the purpose is to protect the parts inside the pump: such as the shaft, stator, bearings, heat sink, electrical panel …

- Electric motor: Usually made of aluminum or stainless steel, used to protect the parts inside the pump chamber: Impeller, pump wheel, mechanical seal…

Technical standard water pump installation instructions

Depending on the type of pump, there will be a little different way to install the water pump, the sharing of 1FIX below only partly helps you to have a better picture, you should refer to the information provided by the brand in detail. machine manual.

1. Water pipes

The water pipe should be fitted to the hose holder so that the hose does not transmit pressure or vibration to the pump head. The inner diameter of the pipe depends not only on the length of the pipe but also on the design flow rate: The diameter of the pipe must ensure that the flow rate does not exceed 1.4 – 1.5 m/ s at the suction end and 2.4 – 2.5 m/s at the discharge end. The diameter should never be less than the pump aperture diameter.

2. Suction head

- The nozzle should be as short as possible, without clogging, without abrupt change of direction.

- A sealing ring shall be provided to withstand the vacuum force generated during suction.

- Must be installed gradually towards the pump head, without kinks that interfere with the priming process of the pump or prevent the pump from being primed.

- In order for the pump to work, a suction valve must be installed. If it is a self-priming pump, the suction valve can be replaced with a check valve mounted directly on the suction aperture. For the pump to work properly, the tip of the suction hose must be submerged under water at least twice the diameter of the hose.

3. Exhaust pipe

The exhaust pipe must be fitted with a check valve and a throttle valve. The check valve protects the water pump from clogging and prevents water from flowing back into the impeller when the pump stops suddenly. In addition, the throttle valve has the effect of regulating the flow.

Insert the pressure gauge into the exhaust manifold. For self-priming pumps, the discharge pipe must have a straight line at least 10m long.

4. Electrical connection

Select the appropriate size wire based on the length and amperage index recorded on the water pump (1mm2 copper conductor cross-section equivalent to 5A). Prepare the grounding and power supply terminals so that they cannot come off during connection. The electrical connection must be done by a technician and must be connected according to the instruction diagram.

The water pump must be grounded and the grounding system must be in good working order. On some single-phase models, the electric motor is protected by a device that can shut off automatically.

The motor, if disconnected due to thermal equipment operation, may restart unexpectedly, so the power must be disconnected before servicing or repairing the water pump. Both single-phase and three-phase pumps should have a suitable electrical protection device (switch with a thermal tail, etc.) that can disconnect the motor from the source.

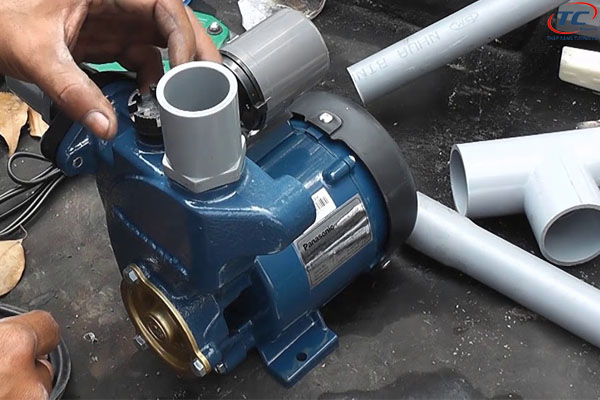

5. Start up

Before starting the water pump, check that the motor shaft can rotate freely. Some water pumps have a small groove on the shaft end on the impeller side. When the pump is stuck, insert a screwdriver into this small slot and then gently tap it with a hammer. Start the water pump only when the pump and suction hose are filled with water. Do not let the pump run dry, if it runs for a long time, the wings will be damaged, the water divider compartment leads to engine fire …

With a three-phase pump, the motor must be positioned in the direction of the arrow drawn on the pump body (clockwise when looking at the motor from the impeller side). If the motor is set in the wrong direction, the connections of the power leads from the source must be reversed. The pump is only allowed to operate according to the specified parameters.

If you want the pump to operate outside the specified range, you can adjust the gate valve on the suction hose or adjust the pressure of any of the pressure relays.

Notes when installing the water pump

Please consult with P69 Company immediately the following notes when installing the water pump!

1. Water pump installation location

– Must be fixed, firmly to avoid the machine shaking when moving will damage the mechanical parts of the pump.

– Must be placed in a dry location, shielded from sunlight, rain or wind or splashed water to wet the motor will cause fire and electric shock.

– As close to the water source as possible, note the ability to suck deeply depending on the type of pump. The suction depth (from the machine to the water surface) of the pump is not more than 9m (for shallow suction pumps). The electronic booster pumps need a higher water source than the pump from 1m.

– Do not place the pump in a space that is too narrow, dry, clean, and airtight.

2. Notes when choosing pipes

– Standard pipe size 1 inch (ɸ 27) must be used.

The water inlet and outlet pipes must be tight, any leakage can damage the pump when operating.

– Do not use too many 90-degree connectors, it will prevent water from coming out, affecting the ability to push high.

– The suction pipe must be installed so that the one-way suction valve is always in the vertical direction to increase pump efficiency.

– The one-way suction valve should be at least 30cm from the bottom of the well to avoid clogging – damage to the water pump.

Price list for pump installation service

With P69 Company ‘s pump service department , we can repair and install all types of water pumps including booster pumps, push pumps, sewage submersible pumps… The job can be done. performed on site or in our fully equipped workshop.

| SERVICE | UNIT PRICE | NOTE |

| Install booster pumps for weak water sources. | 300,000 VND – 400,000 VND |

Depends on the difficulty of construction.

|

| Install the water pump | 300,000 VND – 400,000 VND |

According to the actual work – water supply, power supply.

|

| Replace water pump | 200,000 VND – 300,000 VND |

Depends on the difficulty of construction.

|

| Repair water pump | N/A |

Quote by status and workload (after free survey.)

|

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA