Nowadays the use of PPR plumbing installation is increasingly popular. For large projects, they not only use PPR heat-resistant plastic pipes for the hot water system, but they use PPR pipes in the entire plumbing system. And it is more convenient that when there is a breakdown or leak, we still have an effective PPR heat pipe welding method. Today, let’s learn with P69 Company how to install PPR water pipes, as well as quote PPR water pipe installation prices under the following article:

Things to keep in mind when installing PPR . water pipes

– Do not use PPR pipes to conduct or let the product come into direct contact with toxic chemicals, especially acids.

– During the construction process, it is not recommended to use ppr pipe products that have been broken, cracked or deformed.

– It is absolutely not recommended to use other types of products and materials (Not PPR materials or other brand’s PPR products) to connect with PP-R pipes and fittings. This may cause water pipe leakage during use due to different plastic materials, so you need to be aware of this.

– Do not use hammers or other hard objects to strike PPR pipes and fittings. Do not install plumbing in areas where tremors are frequent.

– Do not use fire or other manual heating methods to adjust the pipe as desired. You should use a dedicated PPR heat welding machine when you want to connect or weld PPR pipes.

– For outdoor water pipes, you should not use normal pipes, but use UV-resistant pipes and fittings (Vesbo UV pipes and fittings) to ensure the safety of the water supply system.

– For plastic shrink and shrink ball valve, only used for cold water supply line. And must be welded after the pressure relief valve (in case the building has a pressure reducing valve installed).

Application of PPR pipe in construction industry

PP-R plastic pipe application field:

– Civil construction (used to conduct hot and cold water in daily life).

– Industry (used to carry oil, highly corrosive liquid, nutrient solution, food, …)

– Agriculture (irrigation, …)

– Medical (for clean water supply systems in hospitals)

– Used for pipe systems of factories using solar energy…

PPR . plumbing installation instructions

Customers use the welding method using coupling according to the following steps:

Step 1 : Cut flat and clean the ends of the pipe to be connected.

Step 2 : Heat the end of the pipe and the joint to be glued.

Step 3 : Squeeze the end of the tube into the joint to be glued and hold until the joint is solid.

How to maintain PPR water pipes

For proper maintenance and long service life, PPR pipes should be protected against displacement, strong shocks, intermittent vibrations, and any form of mechanical impact. Therefore, ppr plastic pipes should not be placed vertically but horizontally in the warehouse and should not be loaded more than one and a half meters (1.5m). The ppr pipe must be stored at a minimum temperature of +50 degrees Celsius.

Price list of PPR heat pipe welding – install PPR heat pipe at home

| Service | Unit price | Note |

| PPR . Pipe Welding | From 250,000 VND |

Subject to condition – location – survey before quote

|

| Install hot water pipes | From 250,000 VND |

Subject to condition – location – survey before quote

|

| Repair broken negative pipes | From 250,000 VND |

Subject to condition – location – survey before quote

|

Why should use PPR heat pipe, PPR heat resistant plastic pipe?

According to the share of a worker with many years of experience in welding heat pipes, he will explain to you why PPR pipes are so widely used:

- PPR pipe has high heat resistance from 70 degrees C to 110 degrees C.

- PPR pipes currently have 4 levels of increasing pressure as follows: PN10 < PN16 < PN20 < PN25. Usually PN10 and PN16 use cold water load; PN20 is used for domestic hot water load; PN25 is used to load water with high pressure for industrial use.

- The pipe has the characteristics of mechanical strength, flexibility, lightness, malleability and resistance to large loads. Especially, the PPR heat-resistant plastic pipe can withstand a pressure of 5mpa (50kg/cm2), so the product is malleable and resistant to strong impacts.

- PPR plastic pipes have many colors, the popular ones are green, gray, white and blue. Due to the presence of activated carbon, PPR water pipes are resistant to the effects of ultraviolet rays, the darker the color, the less UV rays will be absorbed, so it will take a long time to age in the sun.

- PPR pipes are not subject to abrasion and deposits by hard water ions and chemicals such as acids and bases in water, eliminating the possibility of rust like metal pipes, so it is very suitable for installation in all environmental conditions. weather fields and buildings with different uses.

- If installed according to standards and operated, using the right techniques as well as performing PPR heat pipe welding to connect pipes in the right way, the life of PPR heat-resistant pipes can last for more than 50 years.

- PPR heat-resistant plastic pipes are classified in the group of green building materials, protecting the environment. PPR pipes are approved according to certain standards, specializing in transporting clean water, so they can be used in clean and pure water supply systems.

- PPR water pipes have higher sound insulation than conventional pipes, do not cause noise and vibration when the water flows through.

Instructions on how to weld PPR water pipes

Regarding the method of welding PPR pipes, installing PPR heat-resistant pipes, there are currently two basic and most popular ways: fusion welding and resistance welding. Each method has advantages and disadvantages and different technical requirements, depending on your experience in welding PPR heat pipes, you can use one of two ways to weld PPR heat pipes for indoor plumbing systems.

1. Step 1: Prepare PPR pipes and pipe fittings

– After preparing the necessary pipes and fittings for the connection, use a ruler or specialized measuring tool to measure the weld depth according to the welding standard, mark on the PPR pipe and cut the pipe in the original square with the pipe center line. so that the weld can be as tight as possible. If the cross-section of the pipe is not perpendicular to the pipe wall, it will lead to a leak at the joint, resulting in a leak.

– Before placing in the PPR heat pipe welding machine, you should clean the surface of the cut pipe and accessories to avoid dust, debris on the inner surface and outer surface of the pipe, otherwise it will affect the quality of the pipe. Weld.

– The welding surface of pipes and fittings must be thoroughly cleaned, dry, free of grease, after the oxidation layer has been removed, it must be cleaned with Polyethylene cleaner or alcohol of 96% or more and colorless smooth paper before welding. Welding can only start after the detergent has completely evaporated, the weld depth should be re-marked after pipes and fittings have been cleaned.

2. Step 2: Welding PPR . heat-resistant plastic pipe

There are two basic and most popular ways to install PPR heat-resistant pipes: fusion welding and resistance welding. Please consult with P69 company immediately the following 2 ways:

How to weld PPR heat pipe by fusion welding

PPR heat pipe welding by fusion welding works on the principle of using heat to melt the surface of the pipe and then fuse it together into a homogeneous mass. So it should be noted that the melting temperature between the joints, according to experienced heat pipe welders, if the melting temperature is not uniform between the two joints, it will increase the possibility of causing leaks at the joint. because the link is not tight and homogeneous.

- Insert the welding tip to be soldered to the welding machine and tighten it with a hexagon. Optimum temperature for fusion soldering is at 260 degrees C

- After everything is ready, you put the pipe and fittings to be welded into the welding head and hold it until the machining process is finished, the green light indicates that it is ok.

- The heating time is calculated from when the entire pipe section according to the depth of the weld and the fitting is in full contact with the welding tip.

- This stage requires the process of bringing pipes and fittings into the welding head and the heat processing process must always ensure that the weld is perpendicular to the welding head. After the end of the heating time, we proceed to withdraw the solder from the welding head and slowly put the pipe into the accessory, we will have a uniform weld.

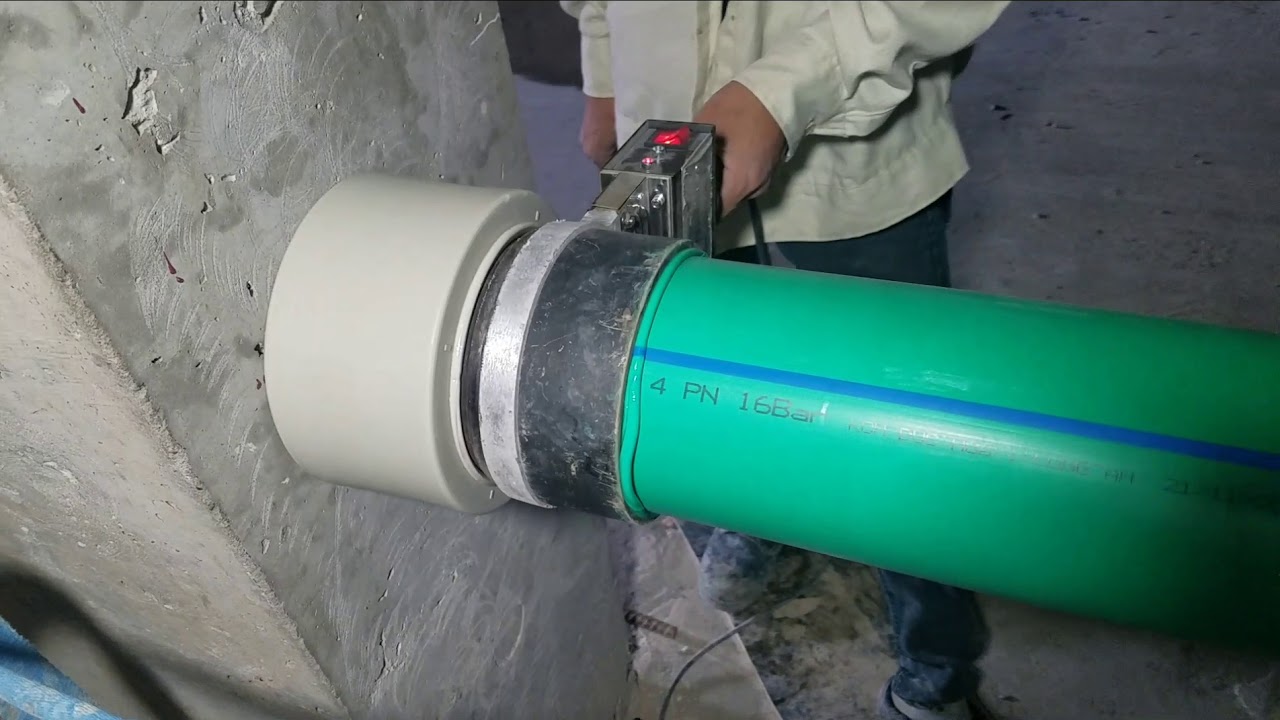

How to weld PPR heat pipe by resistance welding

Bring pipes and fittings to the marked line, when installing, place the power sockets of the fittings in a convenient place for easy operation, the fittings are attached to the pipes in a non-high pressure condition. If the outside diameter of the pipe is large, the welded surface of the pipe shall be scraped until suitable and suitable.

Resistance welding fittings mounted under non-high pressure conditions can be rotated by hand, while there will be cases such as melting of the surface of the fitting or flow into the pipe during PPR heat pipe welding if they are not connected correctly with no high pressure condition.

After completing the preparatory steps, press the confirmation button (ASCERTAIN), the welding machine will display the welding parameters again, after completing the confirmation, press the start button (START-UP) again to start welding. The PPR heat pipe welding machine will automatically signal when the welding steps are complete. Please record the welding parameters, operating time on the pipeline.

During the cooling period, the accessory cannot be moved or the pressure is applied to the outside. There is a safety device (red button) on the accessory, it is strictly forbidden to take it out before or during PPR heat pipe welding.

How to weld a perforated PPR heat pipe

Many incidents of wall drilling, foundation drilling, causing holes in the wall PPR pipes occurred. The characteristic of this type of malfunction is a single hole perforated spool. Here, there are two cases.

1. Spool with 1 hole on 1 side of PPR . tube

At this time, 7mm PPR (for drill bit 6 and below) and 11mm (for drill bit 10 and below) can be used to seal the hole.

How to proceed using a soldering iron, attach the welding rod to the puncture site for about 1-2 minutes, you can use scissors or a welding rod cutter and plaster the wall normally.

2.PPR pipe is drilled on both sides of the pipe

In this case, there is no other way but to cut the broken pipe and then perform PPR heat pipe welding by the method of pipe cage to replace it with another piece. Because it is not possible to access the inner punctured side to use the emergency welding tip as in the case above.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E . M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA