Maintenance of the electromechanical system is an important job, but most construction projects today are not paying much attention to the maintenance of the electromechanical system. This poses many potential safety risks to the structure and people. Today, P69 company will share instructions for maintaining mechanical and electrical engineering systems in accordance with technical standards. To help homeowners or general contractors ensure the safety of perfect works.

What is the importance of the maintenance of the electromechanical system of the building?

It plays a very important role in the operation and use of the project. Directly affects the life of the equipment in the construction. Some constructions are not maintained for a long time, leading to equipment deterioration and unusable. Or the electrical wire is bitten by a mouse, causing an electrical short to cause a fire.

Problems occurring to the electrical system in factories and workshops

Factories and industrial plants often have problems such as:

- Power failure: unstable power supply, voltage is too low or too high, short circuit, ..

- The electrical system is on fire, has an electrical leak, the electric motor is stuck running unstable, ..

- The transmission system suffers from excessive vibration: broken rings, damaged mechanical structures, etc.

- Overloaded substations cause breakdowns and power outages to the grid;

- Controllers and sensors are broken and there are many other problems

- Broken power tools: magnetic starter, relay, fuse.

Types of maintenance of electromechanical systems

There are two forms of maintenance of the electromechanical system that we need to pay attention to:

1. Preventive maintenance of electromechanical systems

It is regular maintenance and maintenance to prevent risks and increase the life of equipment.

This is the most important form of maintenance, but often overlooked by homeowners, or investors. Because it requires regular implementation, continuously on a monthly or yearly basis. Accordingly, all technical items such as: Electrical cabinets, water pumps, ventilation fans, air conditioners, fire alarm systems, fire fighting… need to be periodically maintained by technical staff.

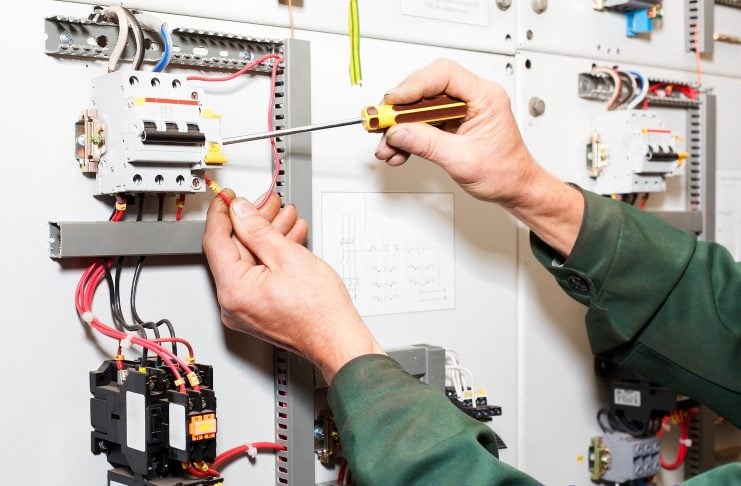

Technical experts come down to the construction site to check the current status of the electrical equipment system (electrical cabinets, lights of all kinds, socket switches of all kinds, wires…). Check water equipment (pumps, water heaters, sanitary equipment…), air conditioning, ventilation. To detect possible errors to prevent equipment failure. Do not interrupt the operation of the project.

The main tasks of preventive maintenance are: Cleaning, changing oil, lubricating, repairing and replacing old damaged equipment and parts, if any.

Technicians keep track of the life of each device so it’s easy to know when to replace parts and accurately diagnose problems when they occur.

2. Maintenance and repair of electromechanical systems

Is the handling of problems of the electromechanical system in the construction.

When an incident occurs, a technician will come to the scene to check and analyze the cause. And assess the damage level of the device to make a repair plan and fix it. Also establish a routine preventive maintenance program.

This form of maintenance is intended to quickly fix errors that arise. Raise the awareness of the investor about the technical maintenance of the works, regular and periodic maintenance of the electromechanical system.

Guidelines for maintenance of mechanical and electrical systems

To ensure that the process of maintenance of the electromechanical system is done quickly and accurately. Service providers of M&E system maintenance need to follow a 5-step process as follows:

1. Step 1: Make a list of machinery and equipment that need maintenance

Make a list of all the machinery and construction equipment that are in use and need to be maintained. In case new machinery and equipment arise, the maintenance department should immediately update the system.

2. Step 2: Survey the current situation.

Technical experts consider each feature and function of specialized equipment. From there, determine how often to maintain and maintain machinery accordingly.

3. Step 3: Make a maintenance plan.

The service provider mechanical system maintenance will base on the survey results to plan maintenance and repair. And submit it to the landlord or investor unit for approval.

4. Step 4: Prepare for maintenance and maintenance.

Proposing necessary equipment and materials for maintenance and purchasing according to the plan approved by the investor. Ensure the implementation of the plan and schedule committed.

5. Step 5: Perform maintenance and maintenance.

According to the given plan, the building maintenance unit will carry out maintenance and maintenance. And sign and take over the maintenance and maintenance minutes, without affecting the operation of the project.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline : 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA