Design and construction of water supply items is a part of the project’s electromechanical system. It plays an important role in the project. Therefore, it requires a high level of construction and professionalism. Today, P69 company will share the Notes when designing and constructing water supply works. To help homeowners or general contractors build perfect works.

Be careful when choosing materials.

- Notes when choosing materials with cold water supply pipes:

– Indoor pipes go in the wall or on the ceiling using PPR PN10 cold pipe. (tube with blue thread).

– For high-rise buildings, water supply pipes in technical shafts use cold pipes PPR PN16. (Pipe with blue thread)

– Pipes outside the house going into the ground can be used with PPR PN10 pipes or PN10 HDPE pipes.

– For large projects, the pipe in the pump station and the propulsion pipe is usually galvanized steel pipe or 304 SCH10 . stainless steel pipe

- Notes when choosing materials with hot water supply pipes:

– Use hot tube PPR PN20 (tube with red thread)

– If the building uses a central hot water supply system. It is imperative that all hot water supply pipes have at least 13 mm thick insulation outside the pipes

– PPR accessories PN20 (Pipe, taper, quail, etc…) are used for both hot water supply and cold water supply.

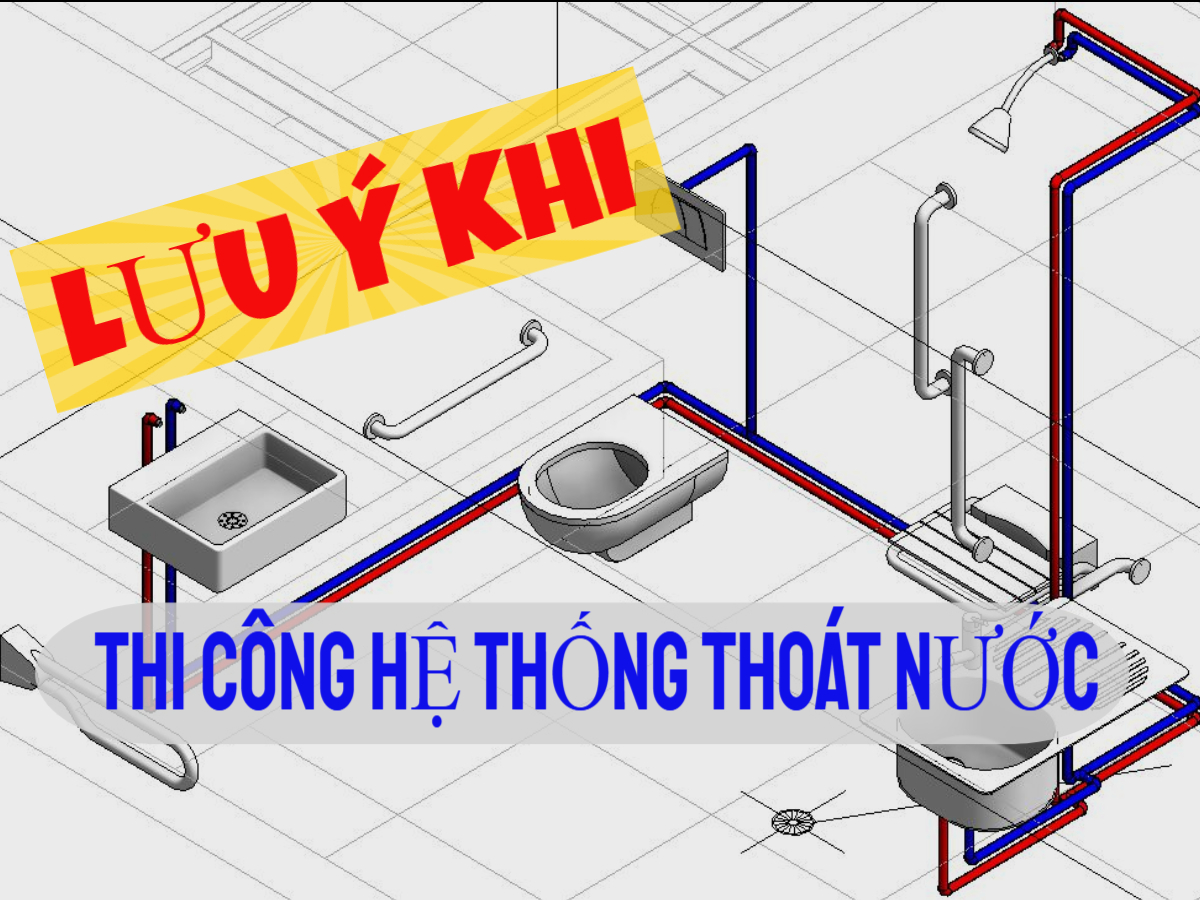

Principle of water supply.

– Shortest pipes to water utilities.

– Separate design of hot water supply and cold water supply

– Designing water supply pipes for convenient use, management, inspection and repair.

– Each branch line does not serve more than 5 water-using devices.

– It is advisable to have a submersible tank to store water and pump it to an overhead tank for convenient use and to drain disinfectants. The pipeline to pump water to the overhead tank and the water supply pipe to the equipment should be made separately, if working together, there must be a one-way valve in position on the pump.

– Installing more roof booster pumps for the top 2 floors

– The average standard of water use per person per day and night is 0.2 m3.

Water supply zoning in the building

– To facilitate the operation, it is necessary to partition the water supply in the building

– For small projects with less than 7 floors, only 2 zones should be divided: Zone 1 provides water for the top 2 floors. zone 2 for the remaining floors below.

– With buildings higher than 7 floors divided into more than 3 zones. Depending on the specific project, the design consultancy unit will divide it reasonably. Or you can contact us for a free consultation. Hotline: 0989.578.569

Construction process of water supply works

– The field engineer of P69 Company will check the design drawings to see if all the elements are complete. Is it suitable for the current state of the project or not. Synthesize design problems to make appropriate adjustments to submit to the investor (landlord) for approval.

– Calculate the amount of main materials and auxiliary materials needed for construction in each stage and send to the owner or the company to buy. If the company purchases materials, the company will present samples of materials to the owner for approval before purchasing.

– Steps of construction of water supply pipes in the wall: Read drawings – get marks by laser – cut grooves – punch walls – weld pipes and fittings – install pipes into grooves – fix pipes

– Steps of construction of pipes hanging from the ceiling: Reading drawings – making impressions with a laser machine – drilling for threaded tyres – installing optical hangers – welding pipes and accessories – installing pipes into optical hangers – welding pipe connections.

– Pressure test the whole water supply pipeline. Seal the terminals, proceed to pump pressure test water. Test time 4h with pressure equal to 1.5 times the maximum working pressure of the pipeline. The maximum allowable pressure drop is 0.5kg/cm2.

Pre-acceptance test of construction water supply items

When construction workers complete each position, technical staff must check the accuracy and completeness according to the approved drawings. Confirm new technical requirements for workers to move to the next stage.

Making as-built drawings

The field engineer after checking and confirming the satisfactory construction status. Measurements and positioning will be carried out to perform as-built drawings.

As-built drawings are the basis for calculating the construction volume. Homeowners rely on as-built drawings to avoid being able to drill into water pipes. And to facilitate future pipeline repair.

Contact us today for a free consultation and answer at:

Contact information P69 – M&E Contractor

Address: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02437688156 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube : https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA