After being installed, the air conditioning system must be sealed. The sealed test gas is nitrogen gas. For systems using NH3, unless otherwise specified in the contract, air may be used for the sealing test. So how does the air conditioning condensate plumb test process work? How many methods are there to test the air conditioning condensate plumbing system? Please refer to the article below with P69.

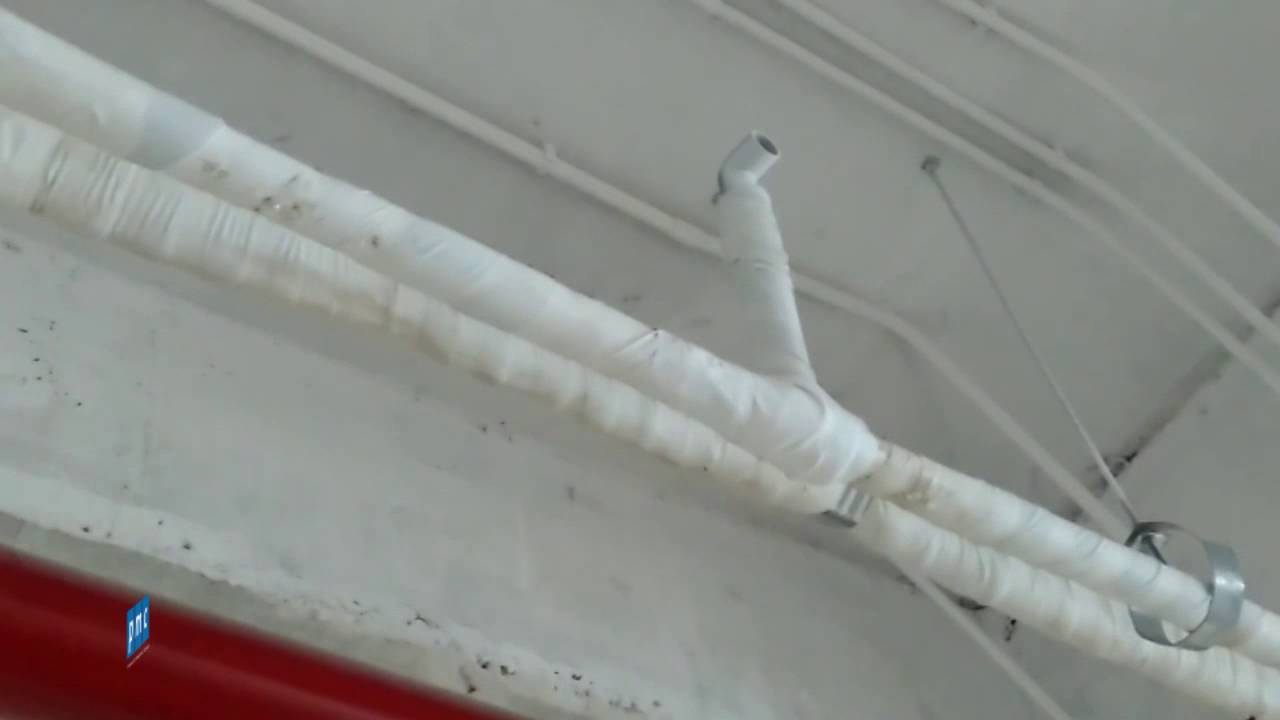

Condensate drainage system

• The condensate drainage system uses PVC pipes with pipe diameters and insulation as specified in the approved drawings and materials.

• Pipeline sealing test includes the following steps:

Test of the through-stage spindle (pipe in technical box):

+ Seal the bottom of the pipe and the main shaft branch inlet pipes. Use spindle stoppers and plugs for branch ends.

+ Pump supplies water slowly into the main shaft pipeline

+ Check for water leakage on the pipe. Only proceed with sealing the connections after the piping has been tested and completely sealed.

Try the branch pipe

+ When testing for tightness of branch pipes, lock the valve on the branch pipe, pour water slowly into the beginning of any branch, monitor the leakage of water.

Insulate the connections only after the piping has been tested and completely sealed

• Make minutes of closed test acceptance

• Make a record of acceptance of construction work

Why should air conditioning condensate plumbing be sealed?

The effects of a leak in ductwork often cause long-term damage to a building. Leaks arise not only from the manufacturer when making products but also from the construction unit when assembling the system. Leaks in the ductwork usually cause the following damage:

– In terms of economics, according to the latest study by Dr. Lan Wills – Naspec Australia, every 10% leak in the condenser water pipe will cause 37% more energy loss. As such, leaky air conditioning condensate systems cause long-term economic loss over their lifetime.

– About the life of the system: for the condenser water system that transmits cold heat, the heat released to the environment outside the pipe causes dew condensation in the pipes and other building components. In addition, the operating intensity of air conditioners, chillers and other equipment must increase, reducing their operating life.

– Regarding the impact on the living environment with special air-conditioning systems, it is necessary to collect and treat smoke and other pollutants, using a leak in the duct system that can spread harmful substances. to the living environment.

Therefore, the work of sealing the condenser water system is one of the important requirements before the system is put into operation.

Test methods for sealing air-conditioning condensate plumbing

Below are the methods of sealing the air conditioning condensate plumbing system you can refer to

1. Intuitive method

– Visually: When the condenser water system is installed, visually inspect the entire system and detect suspicious points such as joints and joints. If there is any possibility of leakage, mark it on the drawing and in the field to promptly fix it.

– By: use a fan to blow into the pipe, then listen to the operation of the system. This can also detect leaks as they often make noise.

2. Method of using testing machine

In this method, we can use specialized machines to check the condenser water system.

The process of sealing the air conditioning condensate plumbing system

1. Open all valves in the system. For solenoid valves, open forcefully or supply power to open the valve.

2. Close all relief valves.

3. Isolate the safety valve.

4. Raise the test pressure to 10bar, then check the welds and joints with soapy water with a spray bottle | or hairy.

5. Mark the leaks.

6. In the event of a leak, the system must be depressurized to atmospheric pressure, and then repaired.

7. Gradually increase the pressure to 12barG. Close the valve that isolates the low-pressure system from the high-pressure system.

8. Try flushing the system with soapy water. If there is a leak, go back to step 5.

9. Raise the high-pressure side pressure to the persistent test pressure, and hold for 5 min. Perform this step when required. No need to do copper piping.

10. Release the high-pressure side pressure to the closed test pressure. All joints and welds are tested with soapy water. If there is a leak, return to step 5.

11. If there are no seals, keep the pressure on the high-pressure side and 12bar on the low-pressure side. Tightness test for 24 hours.

12. After the first 6 hours, the pressure does not decrease by more than 0.3bar, after the next 18 hours, the pressure does not decrease as satisfactory.

13. Quickly open the relief valve on the high-pressure side (usually the high-pressure tank discharge valve and the pressure vessel discharge valve) and leave it there.

Contact information P69 – M&E Contractor

Headquarter: No. 6/165C Xuan Thuy, Cau Giay District, Hanoi

Website: https://p69.com.vn/

Hotline: 02422121212 – 0965937799

Email: kd@cokhip69.com.vn

Facebook: https://www.facebook.com/p69nhathaucodien

LinkedIn: https://www.linkedin.com/in/congtyp69/

Youtube: https://www.youtube.com/channel/UCOUwCnE5iGj8iqe_ZIUM7oA